There are lots of things we all take for granted. Having running, clean water is one; having running, clean water that flows effortlessly is another.

Low water pressure is something that many people believe is just down to bad luck. However, there are certain things we can do to transform a pathetic trickle of a shower into a revitalising cascade of water, for example. One of those things is installing a booster set.

What is a booster set?

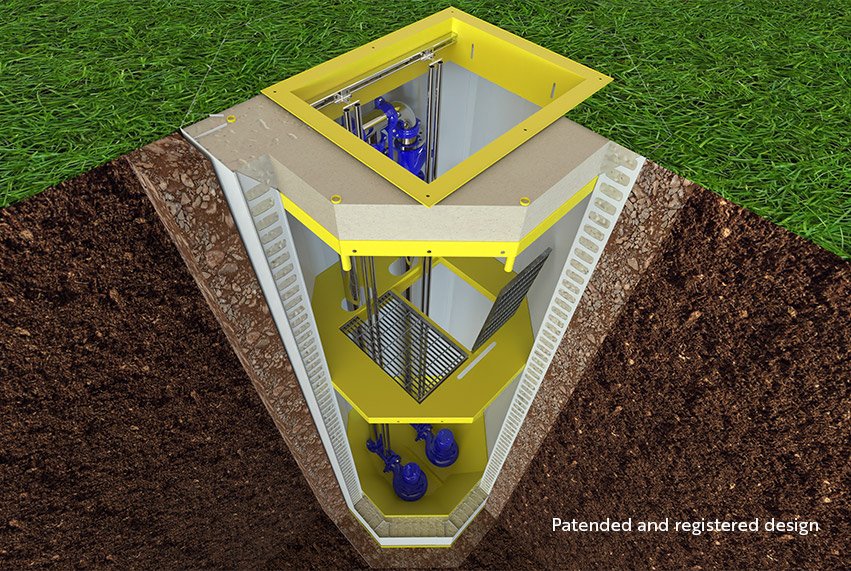

The technical answer to this question is that it is a multi-pump skid-mounted system comprising:

- Normally two or more pumps, commonly with variable speed drives.

- Manifolds, valves and expansion vessels.

- Control gear, sensors and BMS interface system.

The less technical answer is: a pump with pressure control, which automatically maintains a constant pressure in the system.

The main use for a booster set is to pressurise drinking water within the built environment or the mains water network, but booster sets are also used for irrigation, car washes, water treatment systems, industrial processes and fire suppression systems.

How does a booster set work?

The Water Supply (Water Fittings) Regulations 1999 are designed to reduce water waste, misuse and contamination. These regulations do not allow water to be pumped directly from the mains at more than 12 litres/min.

So, in a building where the incoming supply is insufficient to meet demand, the mains supply feeds into a storage tank where it is stored at atmospheric pressure before being pumped around the system by the booster set.

Within the mains water network, booster sets pump directly from a pressurised main (rather than a tank) to give the pressure a real ‘boost’.

Booster sets often incorporate a back-up or standby pump to ensure an uninterrupted supply in the event of a pump failure.

Why are booster sets important?

Compared to other European countries, the UK consumes an incredibly high volume of water every day (around 150 litres per person). The combination of population growth and urban development means this demand for water is not going away and we must do everything we can to improve the situation.

Selecting the right booster set is a vital part of the solution. Because they only deliver the required pressure when it is needed, variable speed booster sets can offer energy savings of up to 50% compared with traditional booster sets. Not only is this good news for the environment, it also means cost savings, too.

But that’s not all; additional benefits of intelligent control include dry-run protection, longer life span of parts (such as motor bearings) and the pump itself, as well as a significantly reduced footprint of the applications (large expansion tanks are not required).

How to select a booster set

Our focus on energy conservation means it is more important than ever to select the right booster set for the job, and this means identifying key data.

Calculated normal demand flow rate: It is up to the system designer to calculate how many taps, showers etc. are to be fitted. Operational diversity (how many systems are likely to be used at once) can be referred against industry standards (such as CIBSE).

Calculated peak demand flow rate: What are the likely scenarios specific to the project? For example, in a rugby club the showers are likely to be used simultaneously, whereas in an hotel, shower usage will be more staggered.

Static height difference between supply tank water level and highest outlet on the system: This is simply the physical measurement between the water level in the storage tank feeding the booster set and the shower or tap on the top floor of the building.

Required pressure at the highest outlet: The system designer will determine the pressure required at the highest point in a building. For example, a 3-storey town house may need at least 3.0 bar pressure to satisfactorily operate a rainhead shower on the top floor. Adding the required pressure figure to the static height and friction loss figure (see below) gives the duty head pressure required.

Friction losses at peak flow rates: This is important if there is any doubt about the size of the interconnecting pipework. If the pipework is too small there will be a significant drop in pressure through the system.

Percentage of pump redundancy required for emergency or maintenance cover at peak demand: Depending on the flow rate specified, the total duty flow could be covered by a single pump or equally spread over two or more pumps. For the latter (each pumping 50% of the peak flow rate required), a third pump would provide 50% redundancy. This means that if one pump failed, the other two could operate successfully at peak demand.

On virtually every project, assumptions will have to be made about this data. This tends to result in over-specification of data to be absolutely sure that the pump system will cope with the demand.

Conclusion

Variable speed booster sets can be used to great effect in homes, hospitals, schools, offices and industrial development sites. This technology is ahead of its time and can help deliver the exact requirements of the end user.

Today’s booster sets can maximise efficiency, minimise water use and cut energy consumption – and they can be retrofitted. If you would like more information about which booster set is right for your next project, contact the team at Dutypoint.

Lloyd Preston

Lloyd Preston  1 August 2018

1 August 2018