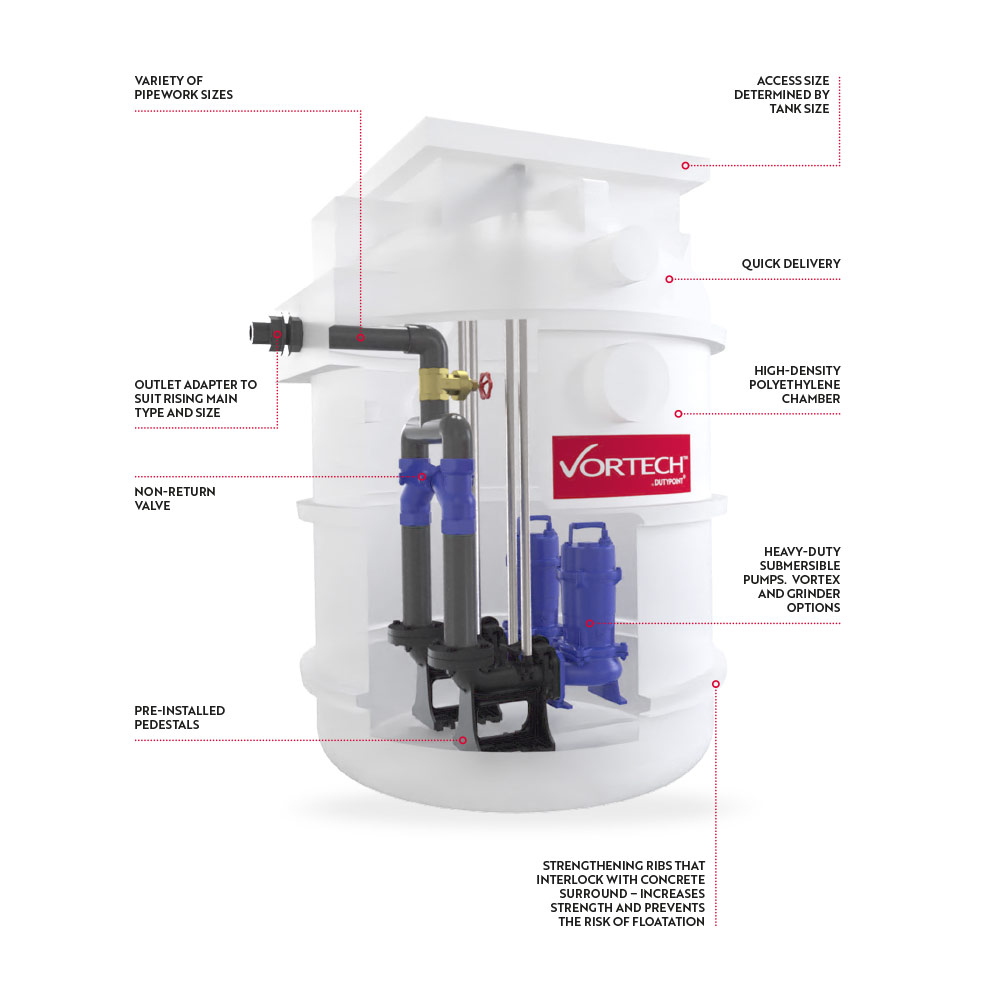

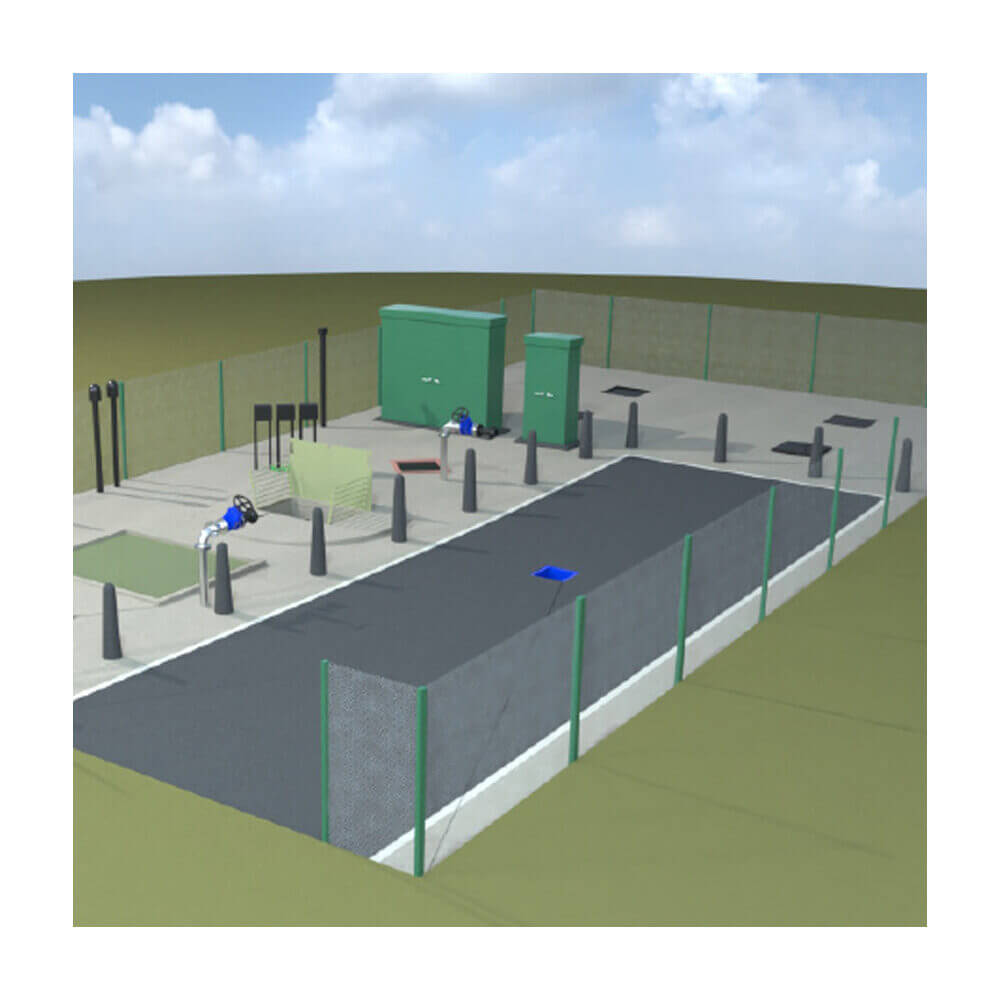

Vortech™ Poly Pump Station

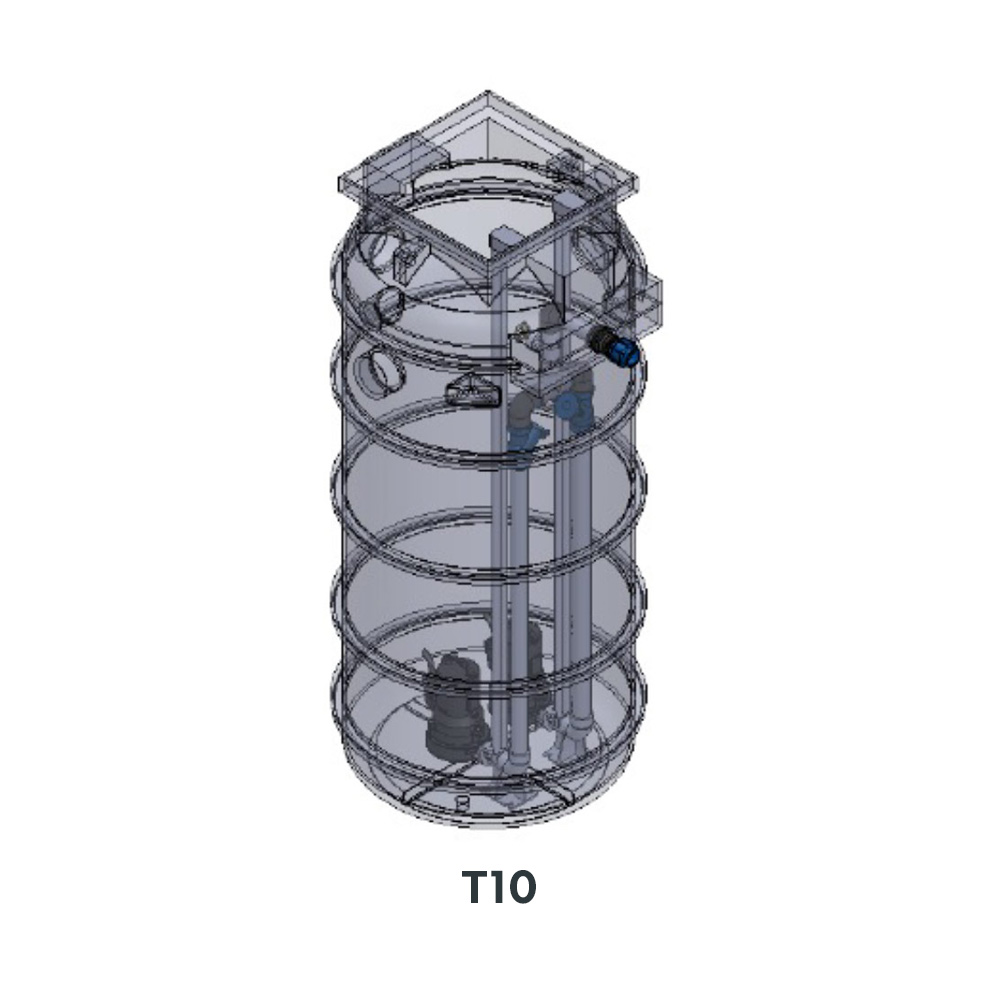

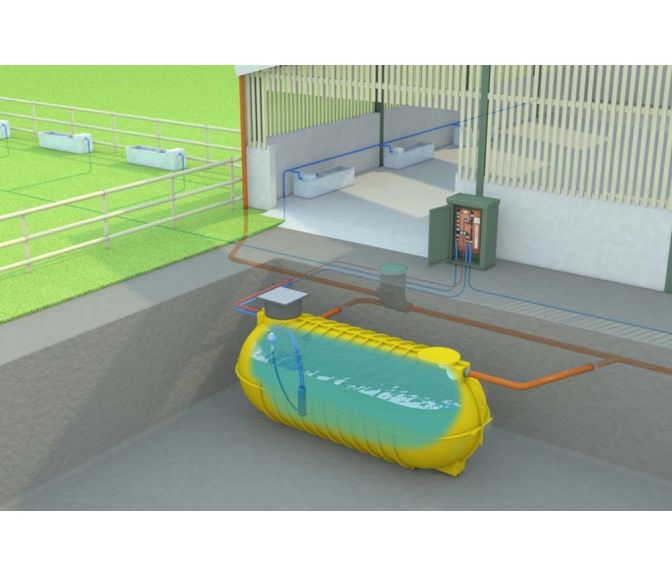

The Vortech™ Poly Pump Station range is a cost-effective family of underground packaged pump stations for domestic and light commercial applications, ranging from 0.6 m to 1.8 m in diameter and up to 4.15 m deep. These systems utilise our high-quality polyethylene rotomoulded chamber, which comes with a 25-year manufacturer’s warranty. The smooth interior finish and specially shaped base minimise sludge build-up, ensuring years of hassle-free wastewater pumping.

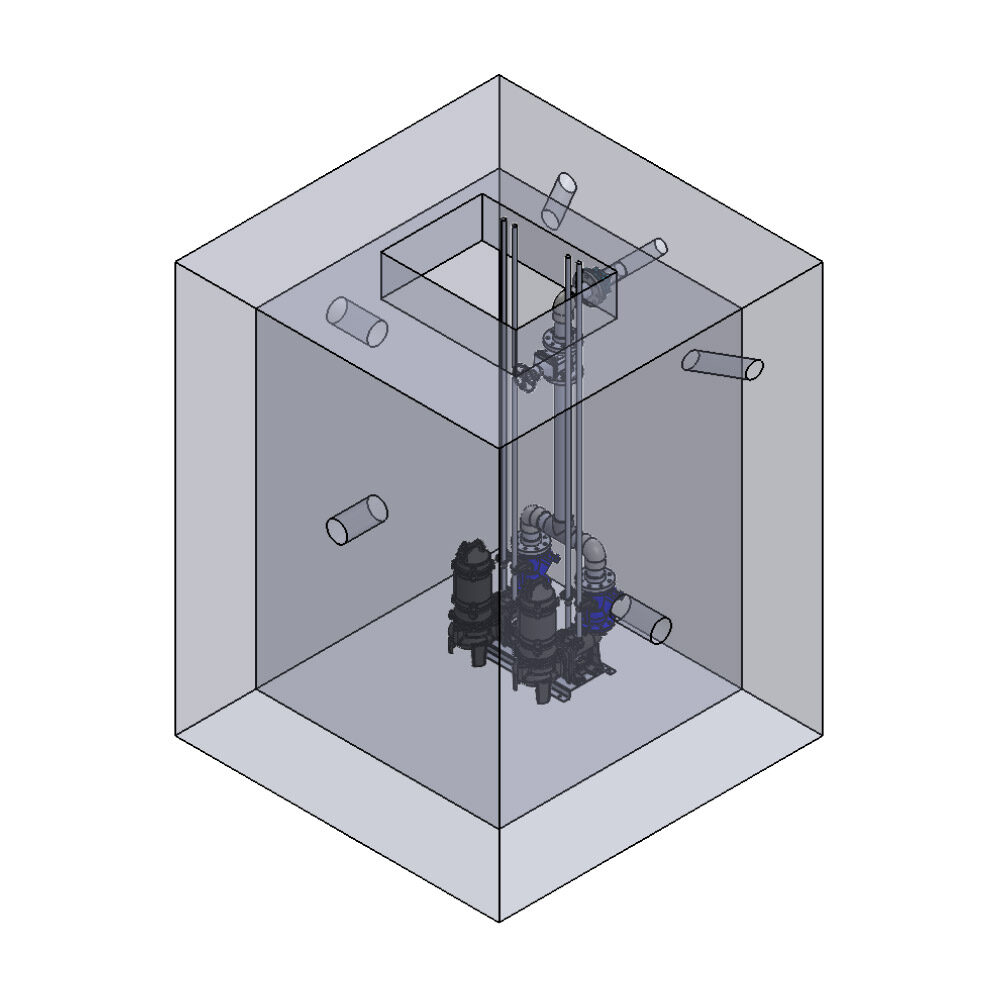

Delivered as complete packaged units pre-fitted with internal pipework, valves and guide rail systems, they take the hassle out of underground pumping stations and installation. Inlet connections are drilled on-site very quickly and easily at any depth and orientation, giving the ultimate flexibility for accommodating gravity inlet pipes and removing the need to specify the exact inlet locations pre-manufacture.

Product specification

Brochures

| Vortech™ Packaged Pumping Stations Brochure |

Manuals

| Operation and Maintenance Manual for Vertical Polyethylene Packaged Pump Stations from Dutypoint | |

| TO6, T10, T15 & T18 Series Polyethylene Underground Tanks Installation Guide |

Control Panel Wiring Diagrams

Product overview

– Ease of installation: Fully pre-fabricated for simple ‘plug and play’ installation, and supplied complete with all necessary inlet and discharge connection fittings

– Ease of maintenance: Auto-coupling (guide rail) pump mounting systems for easy pump access for maintenance/repair

– Hydraulic efficiency: Specially shaped self-cleaning bases minimise dead spots, ensuring any solids are directed straight to the pump suction area, reducing the risk of sludge build-up

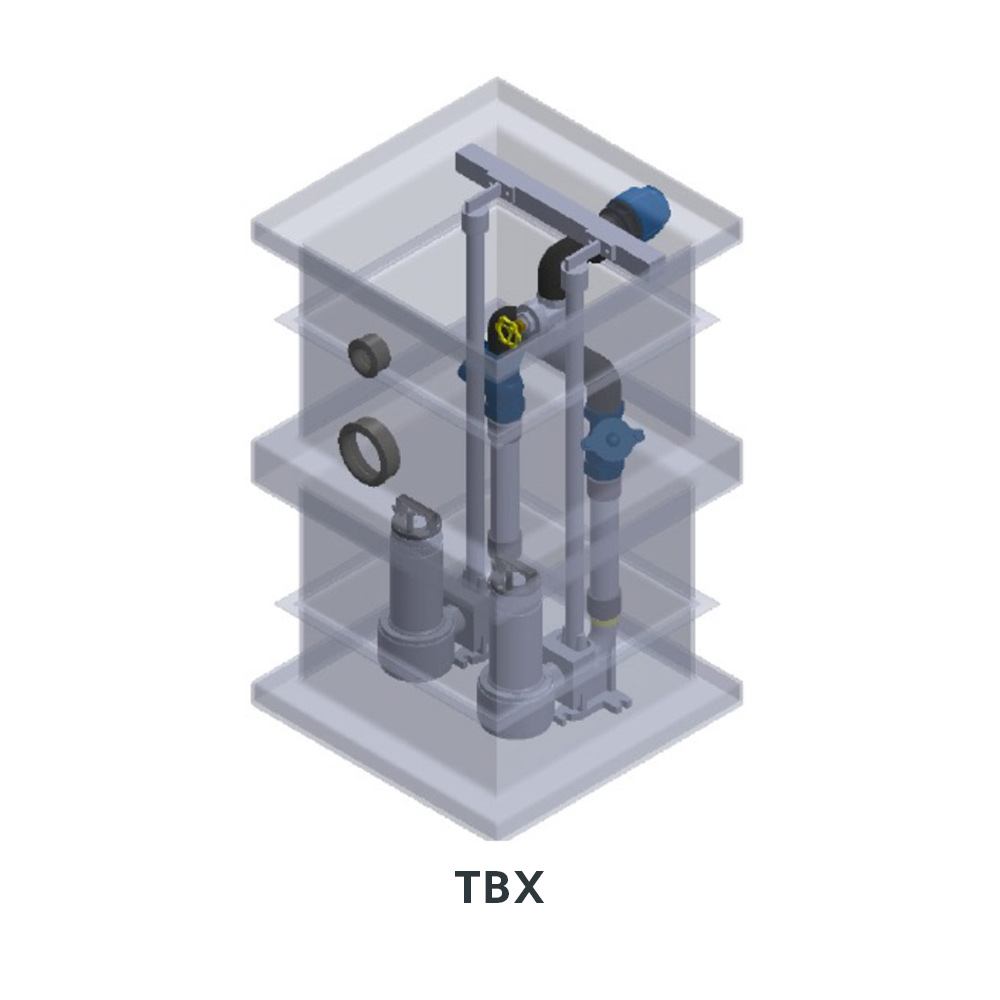

– Flexibility: Large range of chamber sizes and pump options to cover all domestic and light commercial applications

– Industrial control panel: Control panels are hand wired with heavy-duty enclosures, mains interlocking isolators, hand/off/auto selectors, adjustable overloads, power available, run, trip and high-level indicator lamps, 24 V warning beacon terminals, volt-free contacts for connection to BMS for high level and individual pump tripped alarms

Material Specification

Our latest case studies