VR2-0508-LHT

1.1

400/3/50

4.7

VR2-0509-LHM

1.5

230/1/50

18.4

VR2-0509-LHT

1.5

400/3/50

6

VR2-0511-LHM

1.5

230/1/50

18.4

VR2-0511-LHT

1.5

400/3/50

6

VR2-0512-LHM

2.2

230/1/50

25

VR2-0512-LHT

2.2

400/3/50

9.3

VR2-0514-LHM

2.2

230/1/50

25

VR2-0514-LHT

2.2

400/3/50

9.3

VR2-0516-LHM

2.2

230/1/50

25

VR2-0516-LHT

2.2

400/3/50

9.3

VR2-0518-LHM

3

230/1/50

12.4

VR2-0521-LHT

3

400/3/50

12.4

VR2-1003-LHM

1.1

230/1/50

8.2

VR2-1003-LHT

1.1

400/3/50

4.7

VR2-1004-LHM

1.5

230/1/50

18.4

VR2-1004-LHT

1.5

400/3/50

6

VR2-1005-LHM

2.2

230/1/50

25

VR2-1005-LHT

2.2

400/3/50

9.3

VR2-1006-LHM

2.2

230/1/50

25

VR2-1006-LHT

2.2

400/3/50

9.3

VR2-1007-LHT

3

400/3/50

12.4

VR2-1008-LHT

3

400/3/50

12.4

VR2-1009-LHT

4

400/3/50

15.3

VR2-1011-LHT

4

400/3/50

15.3

VR2-1502-LHM

2.2

230/1/50

25

VR2-1502-LHT

2.2

400/3/50

9.3

VR2-1503-LHT

3

400/3/50

12.4

VR2-1504-LHT

4

400/3/50

15.3

VR2-1505-LHT

4

400/3/50

15.3

VR2-1506-LHT

5.5

400/3/50

20.8

VR2-1507-LHT

5.5

400/3/50

20.8

VR2-1509-LHT

7.5

400/3/50

28

VR2-2202-LHM

2.2

230/1/50

25

VR2-2202-LHT

2.2

400/3/50

9.3

VR2-2203-LHT

3

400/3/50

12.4

VR2-2204-LHT

4

400/3/50

15.3

VR2-2205-LHT

5.5

400/3/50

20.8

VR2-2207-LHT

7.5

400/3/50

28

VR3-0508-LHM

1.1

230/1/50

12.3

VR3-0508-LHT

1.1

400/3/50

7.1

VR3-0509-LHM

1.5

230/1/50

27.6

VR3-0509-LHT

1.5

400/3/50

9.1

VR3-0511-LHM

1.5

230/1/50

27.6

VR3-0511-LHT

1.5

400/3/50

9.1

VR3-0512-LHM

2.2

230/1/50

37.5

VR3-0512-LHT

2.2

400/3/50

13.9

VR3-0514-LHM

2.2

230/1/50

37.5

VR3-0514-LHT

2.2

400/3/50

13.9

VR3-0516-LHM

2.2

230/1/50

37.5

VR3-0516-LHT

2.2

400/3/50

13.9

VR3-0518-LHT

3

400/3/50

18.6

VR3-0521-LHT

3

400/3/50

18.6

VR3-1003-LHM

1.1

230/1/50

12.3

VR3-1003-LHT

1.1

400/3/50

7.1

VR3-1004-LHM

1.5

230/1/50

27.6

VR3-1004-LHT

1.5

400/3/50

9.1

VR3-1005-LHM

2.2

230/1/50

37.5

VR3-1005-LHT

2.2

400/3/50

13.9

VR3-1006-LHM

2.2

230/1/50

37.5

VR3-1006-LHT

2.2

400/3/50

13.9

VR3-1007-LHT

3

400/3/50

18.6

VR3-1008-LHT

3

400/3/50

18.6

VR3-1009-LHT

4

400/3/50

22.9

VR3-1011-LHT

4

400/3/50

22.9

VR3-1502-LHM

2.2

230/1/50

37.5

VR3-1502-LHT

2.2

400/3/50

13.9

VR3-1503-LHT

3

400/3/50

18.9

VR3-1504-LHT

4

400/3/50

22.9

VR3-1505-LHT

4

400/3/50

22.9

VR3-1506-LHT

5.5

400/3/50

31.2

VR3-1507-LHT

5.5

400/3/50

31.2

VR3-1509-LHT

7.5

400/3/50

42

VR3-2202-LHM

2.2

230/1/50

37.5

VR3-2202-LHT

2.2

400/3/50

13.9

VR3-2203-LHT

3

400/3/50

18.6

VR3-2204-LHT

4

400/3/50

22.9

VR3-2205-LHT

5.5

400/3/50

31.2

VR3-2207-LHT

7.5

400/3/50

42

Brochure

|

A technical overview of the Dutypoint VR. |

|

Case studies

|

DUTYPOINT WINS IN GRANDSTAND FINISH |

|

Consultant Specification Templates

|

Consultant Specification Template for VR booster sets.

|

|

Certificates

|

VR Booster - WRAS Approval Certification. |

|

|

VR Booster - Kiwa Regulation 4 (KUKreg4) Certification. |

|

Manuals

|

Operation and maintenance manual for the VR booster sets equipped with a Hydrovar inverter. |

|

|

Operation & Maintenance Manual for VR booster sets equipped with Vasco inverters - models containing -LVT or -LVM. |

|

|

Operation and maintenance manual for VR cold water booster set fitted with new Lowara Hydrovar HVL intelligent controller. |

|

Control Panel Diagrams

|

Control Panel Wiring Diagram for Twin Pump, Single Phase (240v) Booster Sets. |

|

|

Control Panel Wiring Diagram for Twin Pump, Three Phase (400v) Booster Sets. |

|

|

Control Panel Wiring Diagram for Triple Pump, Single Phase (240v) Booster Sets. |

|

|

Control Panel Wiring Diagram for Triple Pump, Three Phase (400v) Booster Sets. |

|

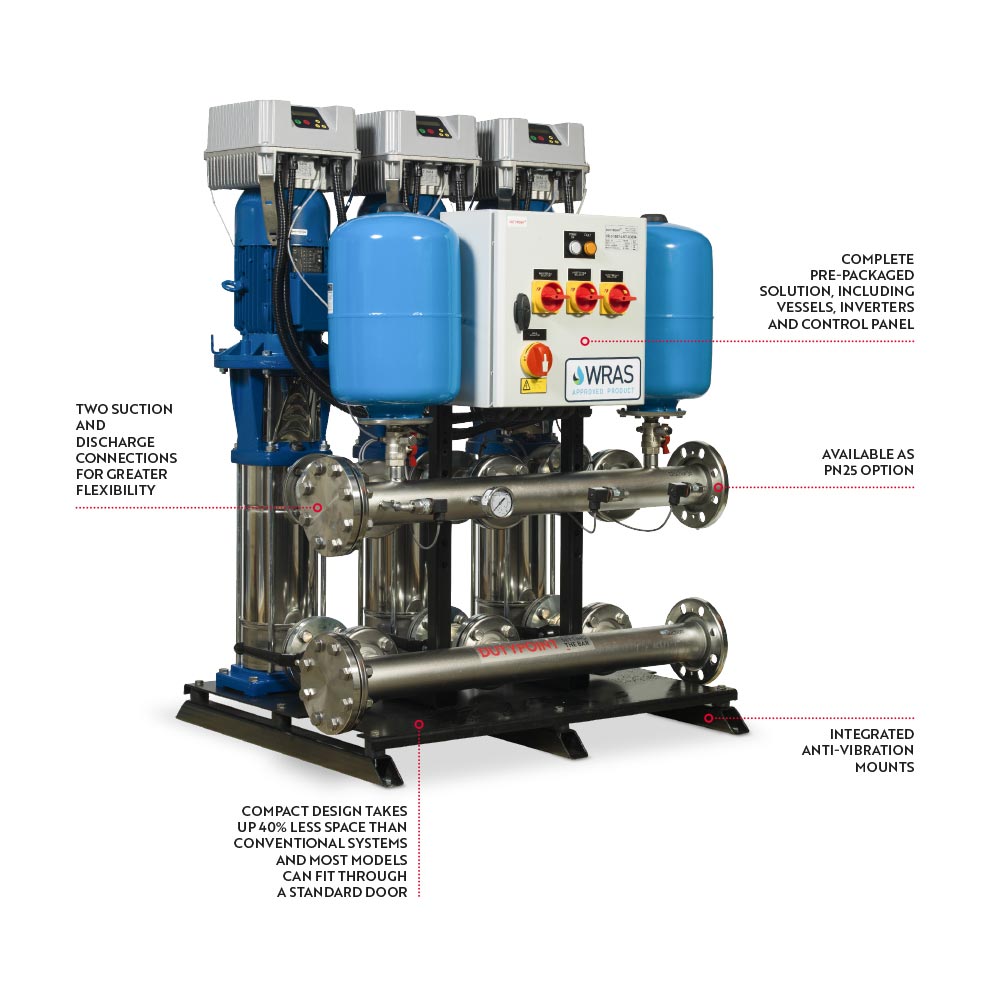

Product overview

– Multistage vertical pumps

– Low-water cut-out contacts in panel

– Anti-vibration mounts reduce system noise

– Pressure set point adjustment

– Hours run recorders

– Local electrical isolation and MCB protection

– IP55-rated control panel allows for simple and safe maintenance

– Cyclic duty changeover ensures even wear across pumps

– Common fault volt-free contact for connection to building management systems

– RS485 connections for connection to Modbus

Pressure range

2 – 16 bar

Max system pressure

16 bar

Controller type

Motor-mounted inverter

Max system temperature

40°C

Noise data

Motor at 2900 rpm < 70LpA (dB +/-2)*

*More specific details available on request.

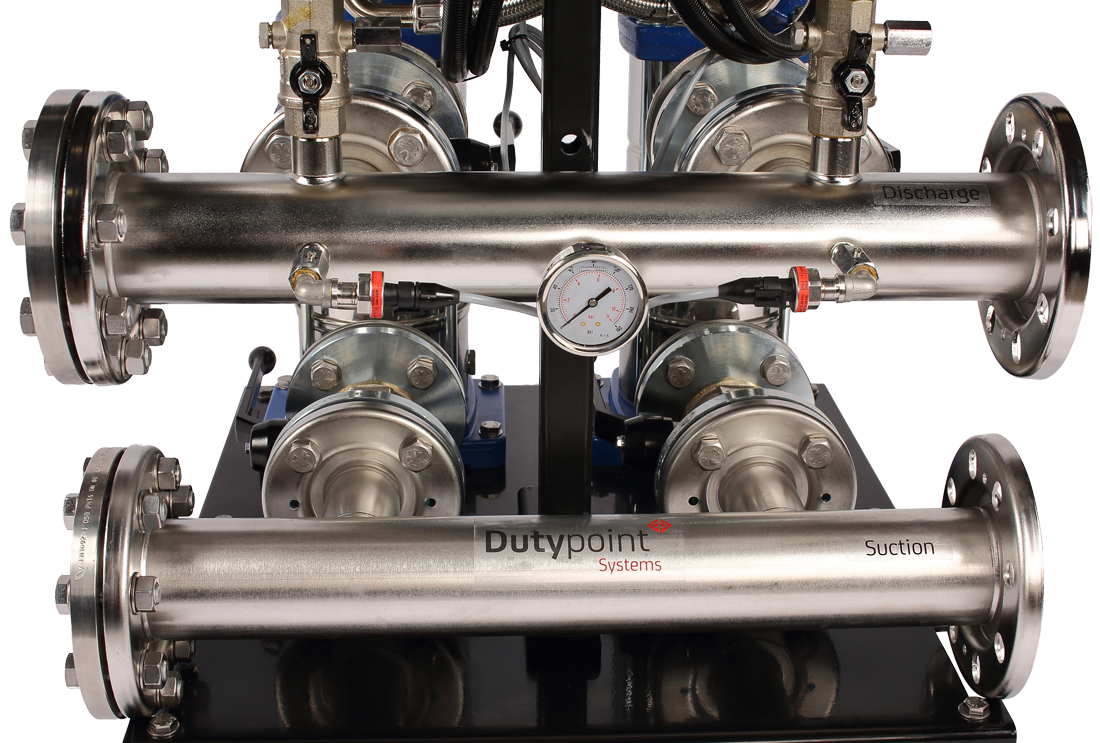

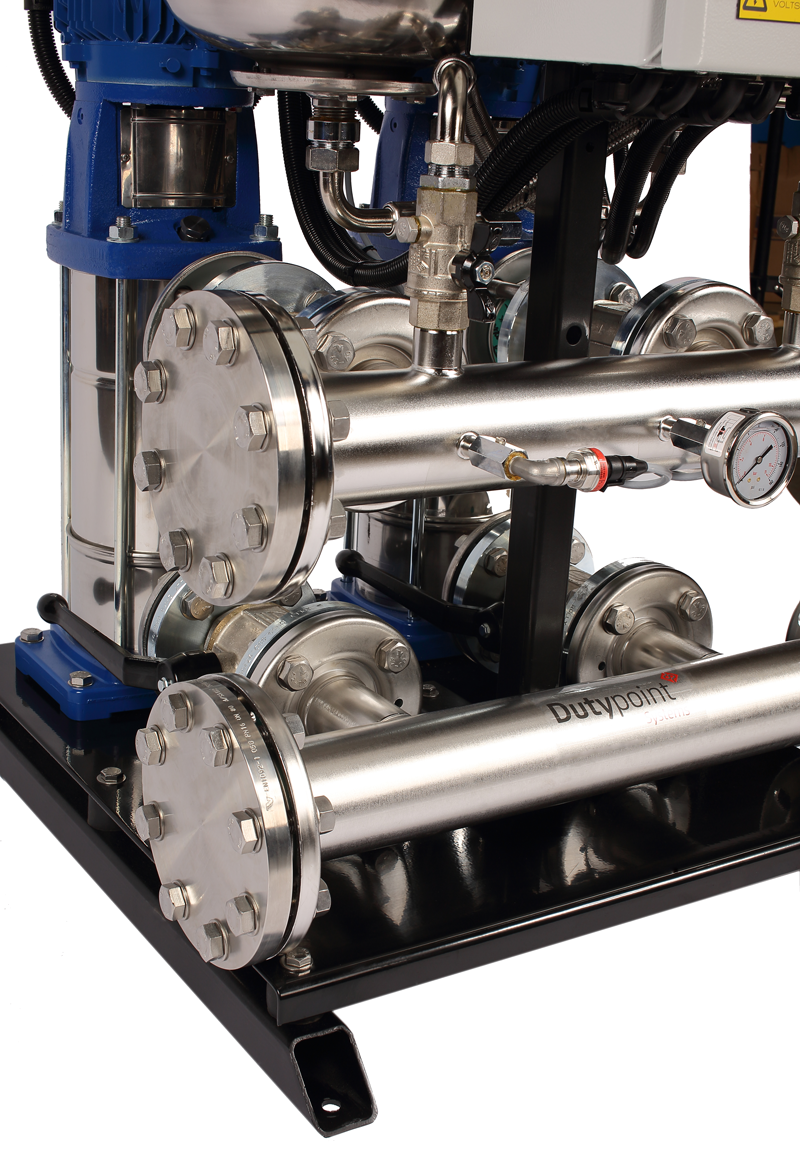

Manifolds

AISI 304 stainless steel

Isolation valves

Nickel-plated brass

Non-return valves

AISI 304 stainless steel

Pressure transducers

AISI 304 stainless steel

Pump casing

AISI 304 stainless steel

Pump impellers

AISI 316L stainless steel

Mechanical seals

Silicon carbide, graphite, EPDM

Pressure vessels

Mild steel, WRAS approved

Base plate

Powder-coated mild steel