Underground Packaged Plant Rooms:

A lesson in safety

Barton Park is a 94 acre residential-led scheme to the north-east of Oxford, England. The development includes plans to build up to 885 new homes, a primary school, food store, community hub and park. (Barton Park Oxford, Grosvenor)

Named as a one of the NHS’s ‘healthy new towns’, a nationwide project aiming to shape the health of communities and to rethink how health and care services can be delivered, it is being built as a sustainable, green community.

Taking on the development for the project, housebuilder Hill Residential were committed to keeping all aspects of the project eco-friendly, safe and up to the best standards.

With a development this size, the infrastructure is crucial to ensure all of the houses get the services they need and further to this, each house needs the right water pressure, which in this case meant adding water boosters to the infrastructure along with the accompanying tanks.

To hide all of this infrastructure and equipment out of sight, Hill chose to go down the route of an underground plant room.

Usually classified as confined space working environments due to the size and way they are accessed, underground plant rooms can be risky places to work in:

“Working in a confined space is dangerous because of the risks from noxious fumes, reduced oxygen levels, or a risk of fire. Other dangers may include flooding/drowning or asphyxiation from some other source such as dust, grain or other contaminant.” (Working on confined spaces, HSE)

For developers, safety is a key concern on any project. With construction still contributing a large proportion of workplace fatal injuries (38 of 144 in 2017/18), developers are often looking for ways to balance the best possible build outcome and the safety of those working onsite.

In order to keep the balance, a traditional underground plant room didn’t seem like the best option for this project as explained by Laurie Pomeroy, the sales manager for Dutypoint:

“One of the challenges of the underground system is this confined space – it is the challenge. You’ve got to be fully confined space trained to even go down into the room.”

This adds significant cost to the project, hiring specially trained engineers and the required equipment quickly adds up, especially when you have to do this 4-5 times a year for maintenance.

“It’s not only maintenance, if your booster set failed, if you suddenly had no water to the houses, you couldn’t even send anyone down there. You’d have to wait to book a visit for two people and all the equipment”

Taking these dangers and costs into account, Hill considered the alternatives and options, asking Dutypoint to consult on the challenges being faced with the plant room.

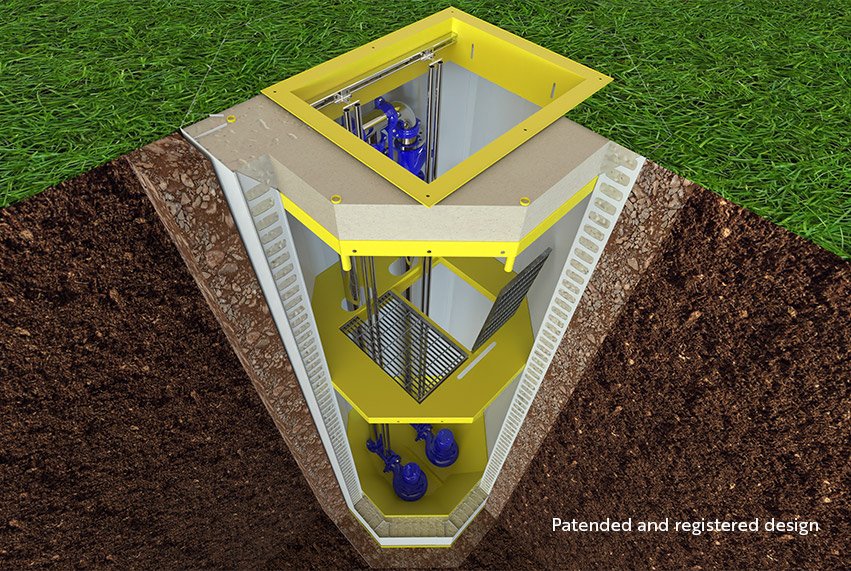

The solution was a new type of underground packaged plant room that removes the need for confined space working, making it a safer and in the long-run, most cost effective.

Dutypoint’s Optimise product, an underground packaged plant room, includes specific safety features to mitigate all risks, including:

- A full-length entry hatch

- full-size integrated staircase

- safety warning beacons

- emergency floodwater storage

The integrated staircase is a major element for overcoming the common health and safety issues of underground plant rooms and when combined with the built-in raised-floor which acts as an emergency water storage tank, known as a ‘bund’, Optimise is a safer option than any other off-site manufactured underground plant room.

Lloyd Preston

Lloyd Preston  12 November 2018

12 November 2018