Video guides and resources

In many cases water companies will be delivering in excess of this minimum requirement, but even at 1 bar, this isn’t always enough to sustain demand in larger residential properties, high rise buildings or commercial and industrial buildings where there are multiple water outlets.

Hello, I’m Frazer Ross and in this week’s 60-second knowledge booster video, I’m talking about calculating the pressure requirement. Having determined how much water we need, we then need to determine at what pressure we need to supply it at.

Hello, I’m Frazer Ross and in this week’s 60-second knowledge booster video, I’m talking about calculating the pressure requirement. Having determined how much water we need, we then need to determine at what pressure we need to supply it at.

Hi I’m Frazer Ross. In this week’s Knowledge Booster video, I’ll pick up from where I left off last week and will talk about determining the pressure requirement for new projects.

Hi I’m Frazer Ross. In this weeks 60 second Knowledge Booster I’ll talk about determining existing standing pressure and the flow requirement for new projects.

According to the official Ofwat Regulations, water companies must maintain a minimum pressure in the communication pipe of 7 metres static head, which is 0.7 bar.

In this video, Jesse Freeman and Chris Lang discuss the many features and benefits of the new VT cold water booster set from Dutypoint.

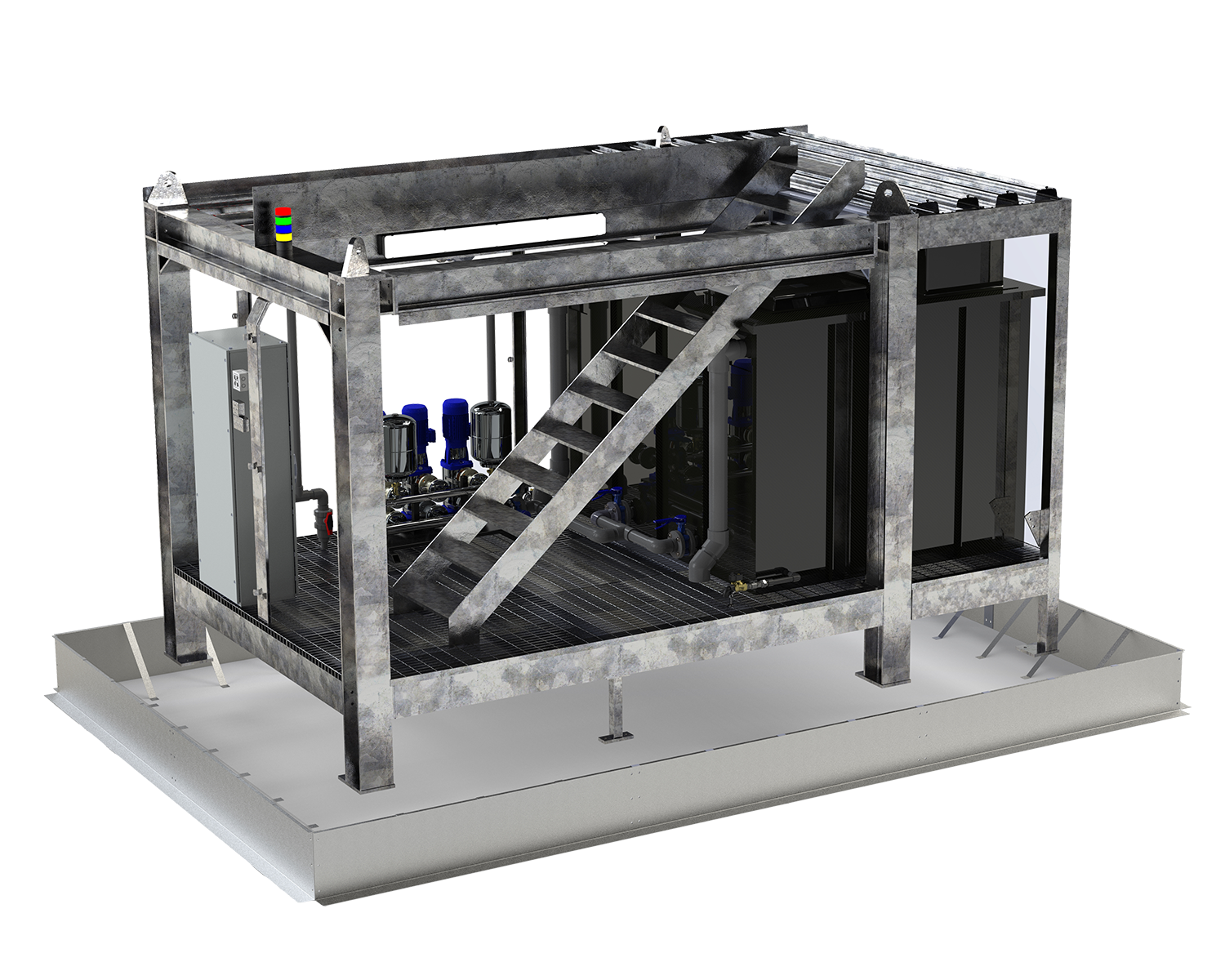

The Dutypoint OPTIMISE Underground packaged plant room provides a cost-effective, safe and efficient solution to plant room space, and for installing water systems underground.

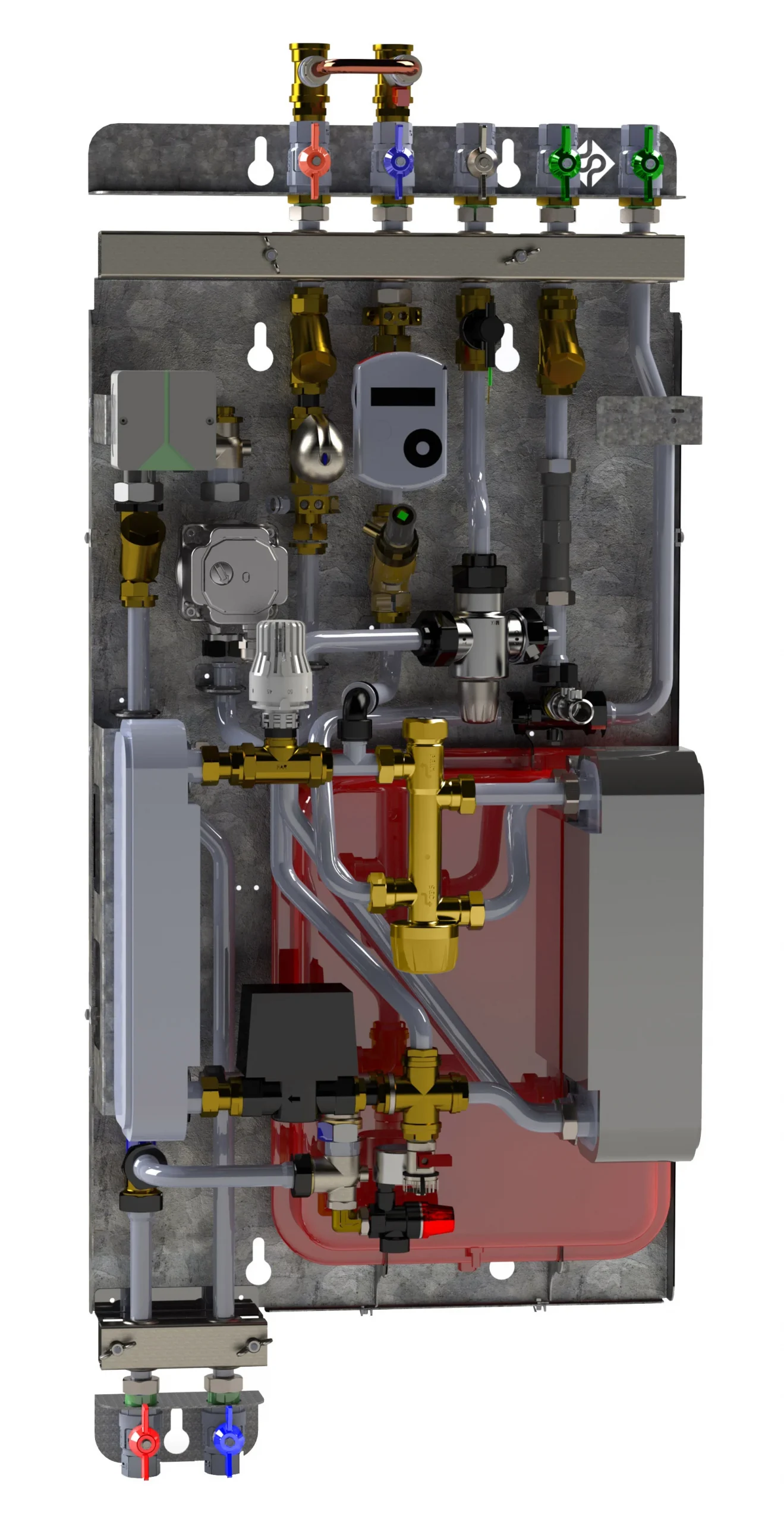

The Element Ultra High-Performance range of cylinders by Dutypoint, specifically developed for boosted hot water systems in high end residential and light commercial properties which have a greater demand of high pressure and high flow.

The Element Ultra High Performance range of cylinders by Dutypoint, specifically developed for boosted hot water systems in high end residential and light commercial properties which have a greater demand of high pressure and high flow.

Cutting-edge, cost-effective Heat Interface Units from Dutypoint Systems

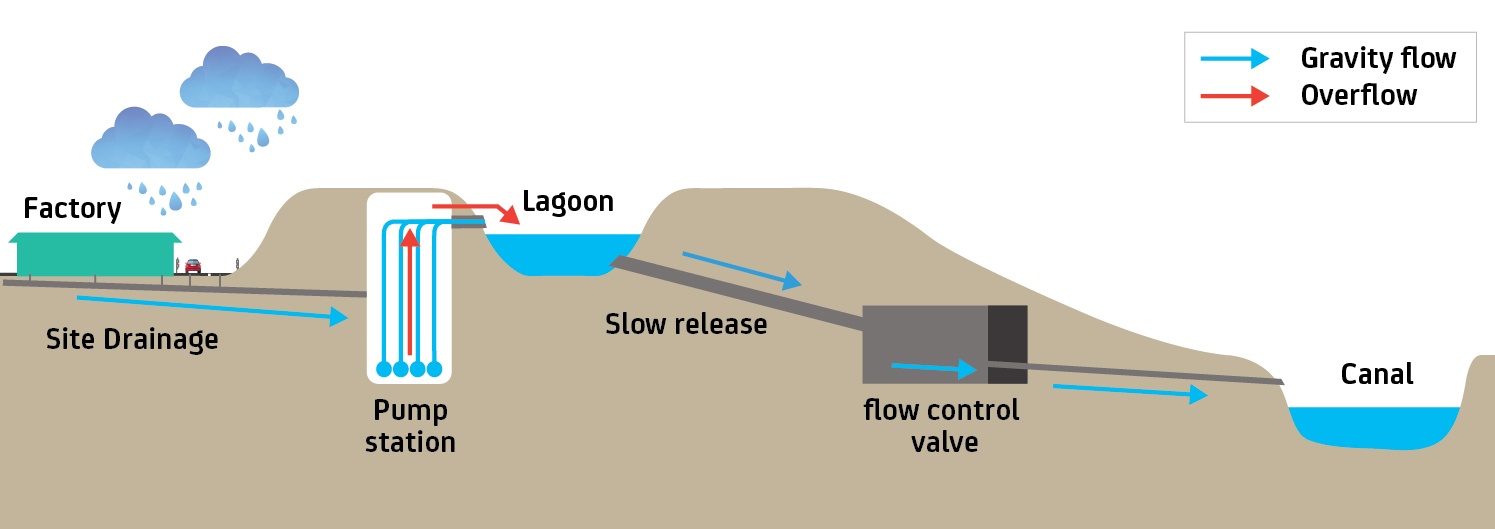

Dutypoint have just commissioned the new 30kw surface water pump station protecting a manufacturing facility in the West Midlands.

In this video, we give a brief overview of the various components that make up a Dutypoint ScubaTANK.

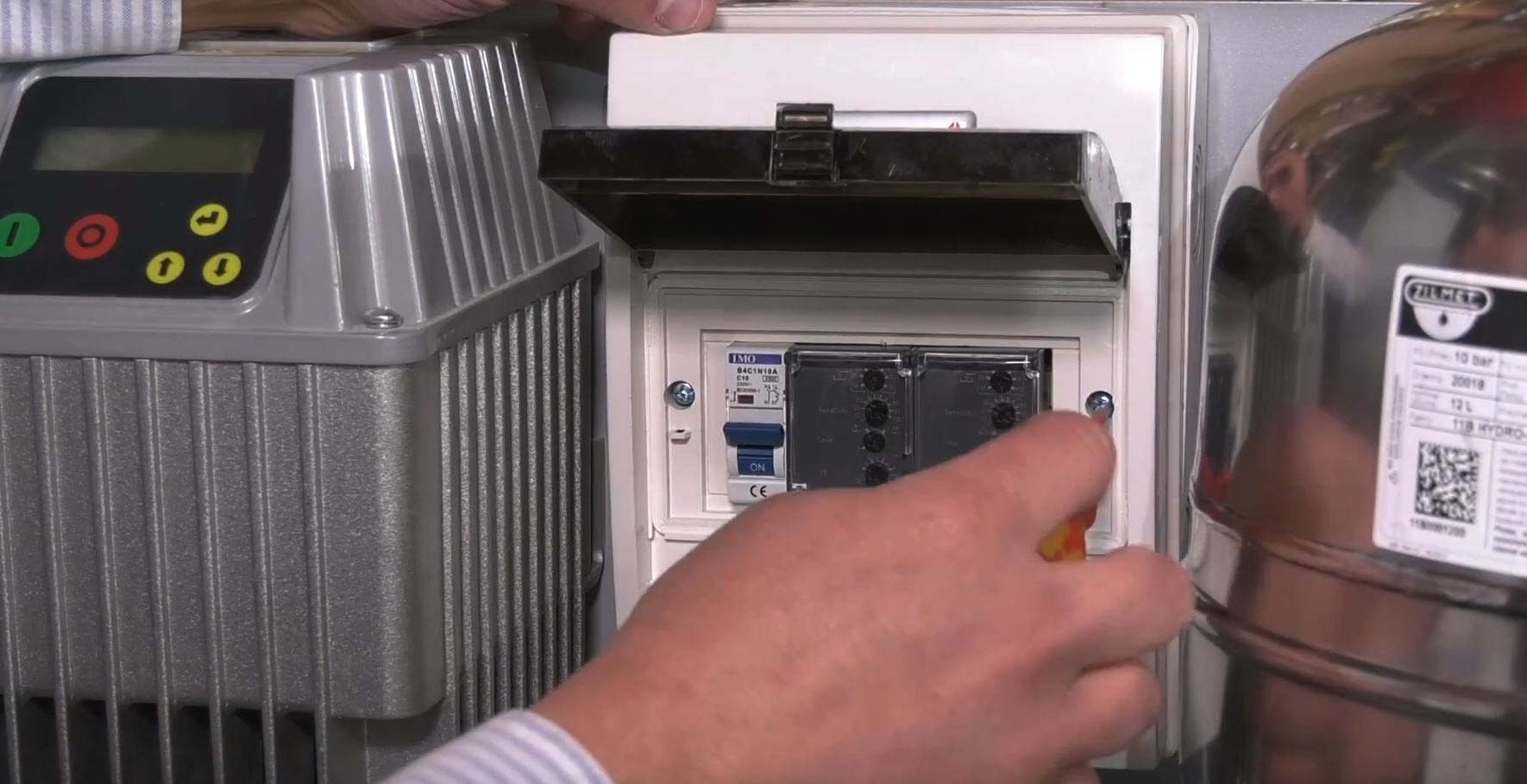

A guide to help with accessing the volt free contact terminals.

Remote BMS enable / disable function explained.

Installation video for the horizontal split ScubaTANK from Dutypoint.

Hear what a top plumber has to say about the ScubaTANK water pressure booster.

Daniel Freeman talks about the key benefits of ScubaTANK at the Installer2016 event.

The VR range of twin and triple pump booster sets are designed to produce maximum performance within a minimum floor area.

The VR range of twin and triple pump booster sets are designed to produce maximum performance within a minimum floor area.