One box, that ticks all the boxes

Offsite production solutions from Dutypoint

5 reasons why offsite

packaged plant rooms

could work for you

– Reduced project risk

– Increased sustainability

– Detailed offsite design

– Improved lead times

– Improved quality control

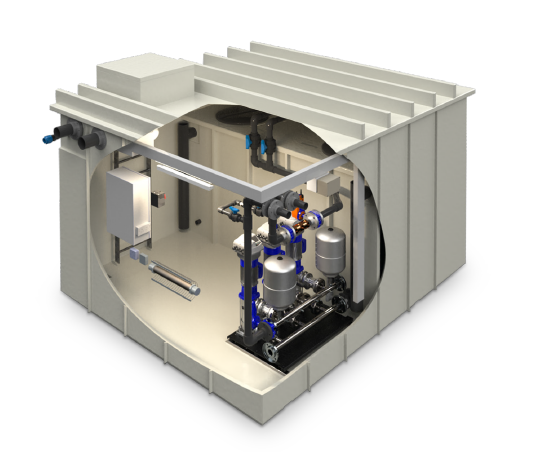

Fulton Road Case Study

A development nestled in the heart of Wembley, just a stone’s throw away from the Wembley Stadium. This project included one energy centre, originally designed as a traditionally built plant room, providing heating and hot water to 800 apartments.

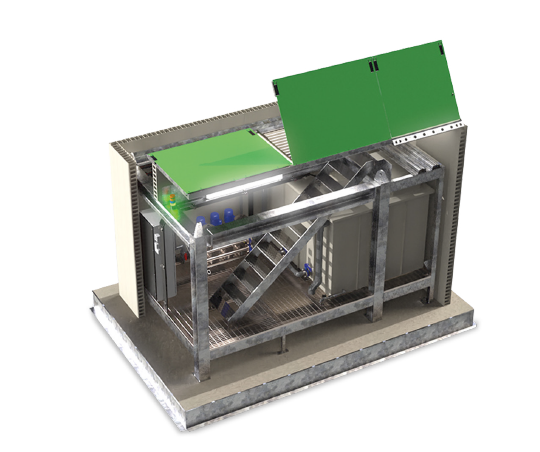

Packaged plant rooms

We work closely with our clients, from design through to commissioning to ensure all required specifications and standards are met. Our packaged plant rooms can be designed to include LTHW, CHW, DHW, and BCW systems, and bespoke builds are available.