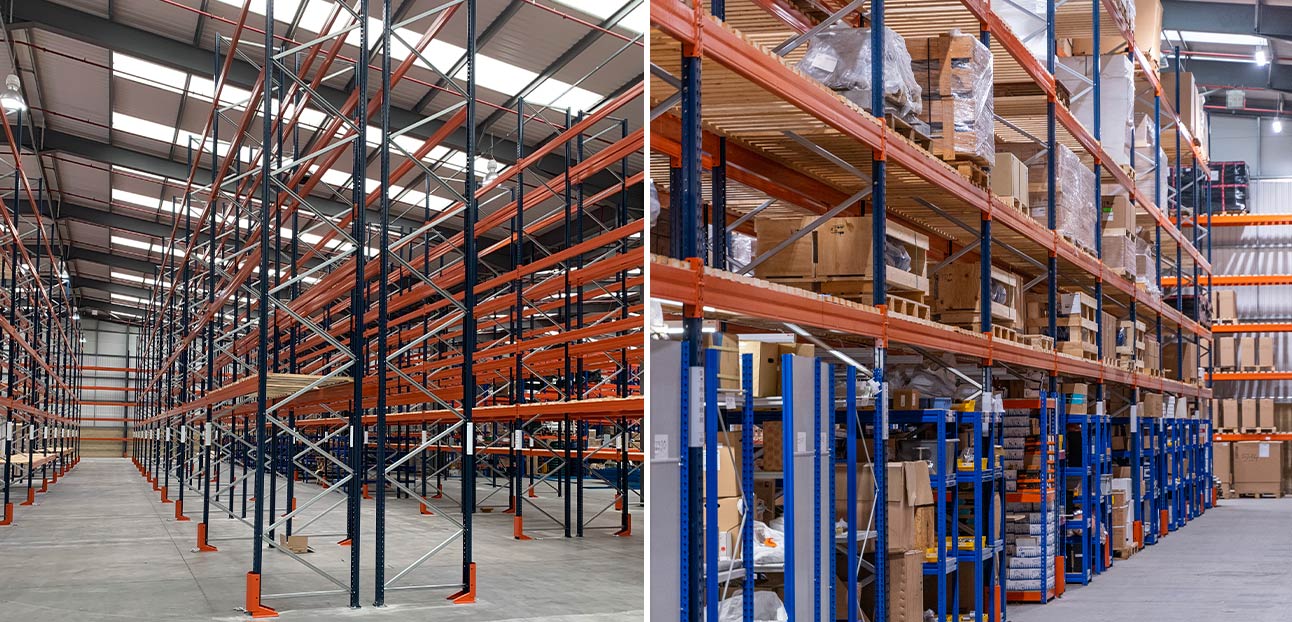

As one of the UK’s leading fluid technology providers, we knew the storage and shelving requirements of our new 100,000 sq ft Gloucester premises needed to be handled professionally and efficiently. At Duypoint, we offer a wide variety of products, ranging from large-format heavy items to individual assembly components. To address this, we engaged the expertise of BiGDUG, specialists in shelving solutions.

Working with our Operations manager, Emma Barnfield, BiGDUG set about designing a commercial storage solution that would embrace our onsite stock, workflow and assembly requirements whilst considering the format, scale and timescales of our site fit-out.

BiGDUG created a system that accommodates off-the-shelf pallet racking, shelving, benches and assembly trollies, all designed to work together, maximising our warehouse efficiency.

Emma Barnfield, Operations Manager, Dutypoint, says;

“If BiGDUG hadn’t provided the product and level of service they did, it would have had an almost catastrophic effect on our business. We work to increasingly tight deadlines, and if we even miss delivery by one day, that could end up with hefty fines from our clients. This project is part of a multi-million-pound new development, so if we say it’s going to be delivered on a specific day, it has to be. I can’t recommend BiGDUG highlight enough.”

The result is a warehouse that can house multiple format pallets, an assembly line that ensures key products such as the Dutypoint ScubaTANK® and Slimline can be manufactured efficiently and an organised working environment.

Adrian Jefferies, Head of Project, BiGDUG, says:

“Dutypoint have a very varied range of components, so a mix of shelving products was supplied, these ranged from racking to store lengths of material, coils of wiring, right down to small nuts and bolts stored in our range of plastic bins and bin kits”.

“I feel Dutypoint had confidence working with us, at the time of the installation, they were consolidating three production units into one large one, anyone who has gone through this process knows it can be stressful, particularly if you are trying to continue with your production schedule. One of our main considerations was to work with Dutypoint, so we caused minimal disruption while at the same time working effectively to install on time with minimum delay”.

Lloyd Preston

Lloyd Preston  10 October 2023

10 October 2023