PROJECT CHALLENGE

As with all highways projects, there is a lot of planning required and this pump station was a major engineering project. Budgetary and time restrictions were a key concern to all involved during the project and Dutypoint knew we had to provide a solution as soon as possible to keep the project on track and help this large project progress.

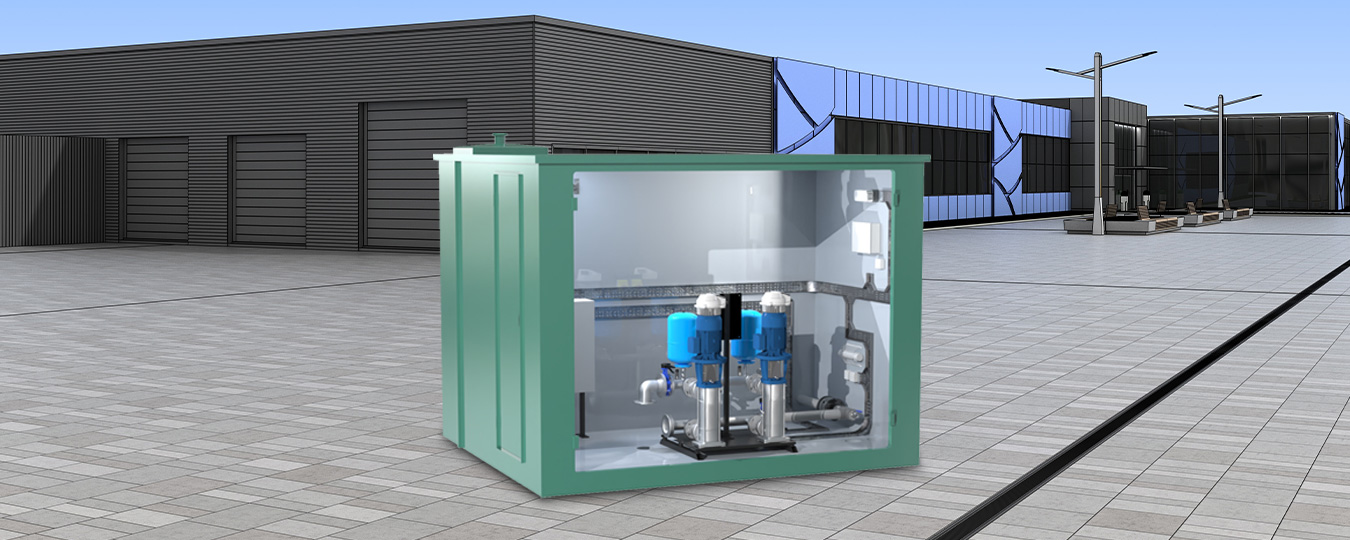

PROJECT SOLUTION

We installed the complete mechanical and electrical installation for a large stormwater pump station as part of this major project. The shaft for the pump station was 6m in diameter and the dig was 15m deep. It was constructed with Cason Ring construction which was installed by the main civil contractor. There was a strict build program for the project and sticking to it was key to ensuring that these works were completed on time and in budget. To guarantee these goals were met, the Dutypoint team worked with the civil engineers and the main contractor throughout the project to design the quickest and easiest methods, utilising off-site build where possible to keep programme as short as we could. An area that offered major programme benefit was the design and install of pre-fabricated baffle wall, estimated to have saved several days of labour intense concrete formwork.

Additionally, to reduce risk, cost and installation time, Dutypoint designed an outfall chamber to reduce the length of the pumping main. This design reduced the length of the rising main and used gravity to transport the fluid under the road and support run-off and stormwater management.

Dutypoint managed the complete installation and project management, including contract lifts, off-site fabrication, design control and installation, testing, and commissioning.

Systems utilised:

6m diameter x 15m deep Cason Ring Chamber

750mm incoming gravity supply

3x 45kW pumps

1050 litres per second

8.5m head

300mm diameter pipework

Lloyd Preston

Lloyd Preston  4 August 2021

4 August 2021