PROJECT CHALLENGE

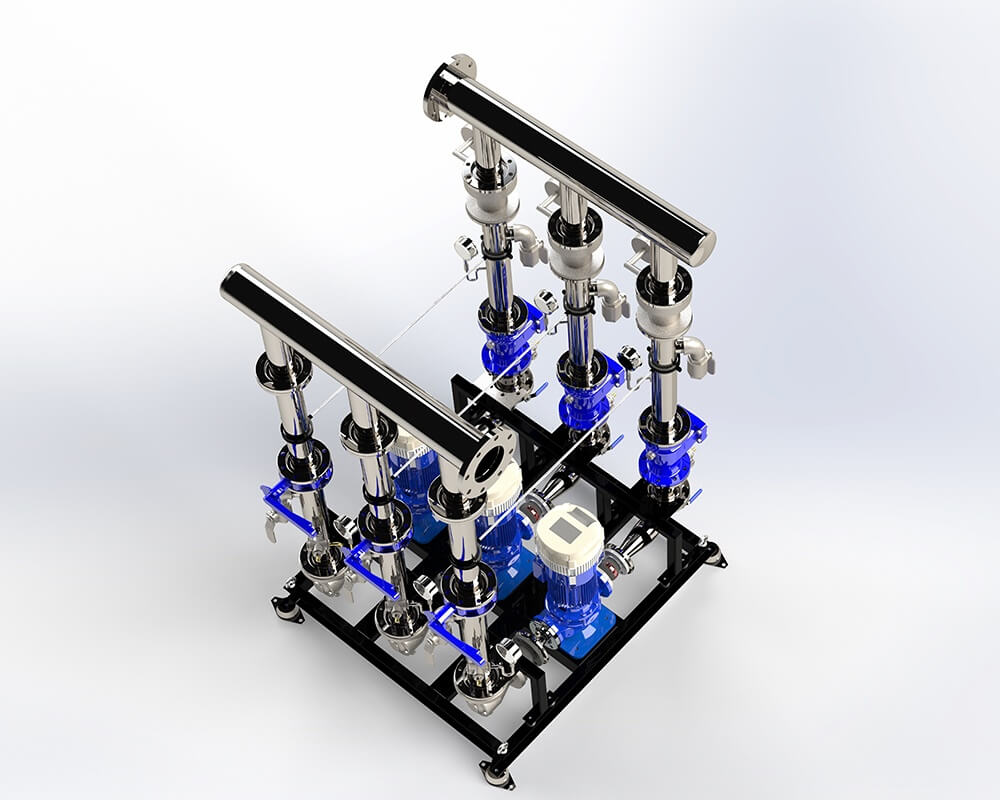

Due to the complexity of the project and the variety of services required, we worked closely with the architectural firm, Heatherwick Studio, to select all the items required for a fully integrated packaged pump solution.

The package included a VR3 booster set, a Cat-5 ScubaTANK®, a pressurisation set and three LTHW circulator pumps mounted on a pre-packaged skid. This skid included a variety of elements from a suction header, flushing points, gauges, pump suction guides, isolation valves, non-return valves, commissioning valve sets and the flow header. All of this was fitted on anti-vibration mounts and included stainless steel pipework.

PROJECT SOLUTION

We worked closely with the Heatherwick Studio design team and provided the drawings in 3D format as they were designing the plant space with computer-aided design software. Pipe dimensions were also designed and manufactured to millimetre tolerances to suit the contractor’s plant layouts and allow for a safe passage into the restricted-access plant room.

To further reduce time and help reduce installation costs and safety risks, a large and complicated section of the plant room was manufactured off-site. This helped keep any associated build schedule disruption to a minimum.

Lloyd Preston

Lloyd Preston  26 October 2018

26 October 2018