PROJECT CHALLENGE

As the water table on site is very high, it required high-power 30kW pumps to successfully move the large volumes of water present to a purpose-built storage lagoon. From there, the excess water would be slowly released back to a nearby canal using a specially designed flow control valve housed in an underground chamber between the lagoon and canal.

PROJECT SOLUTION

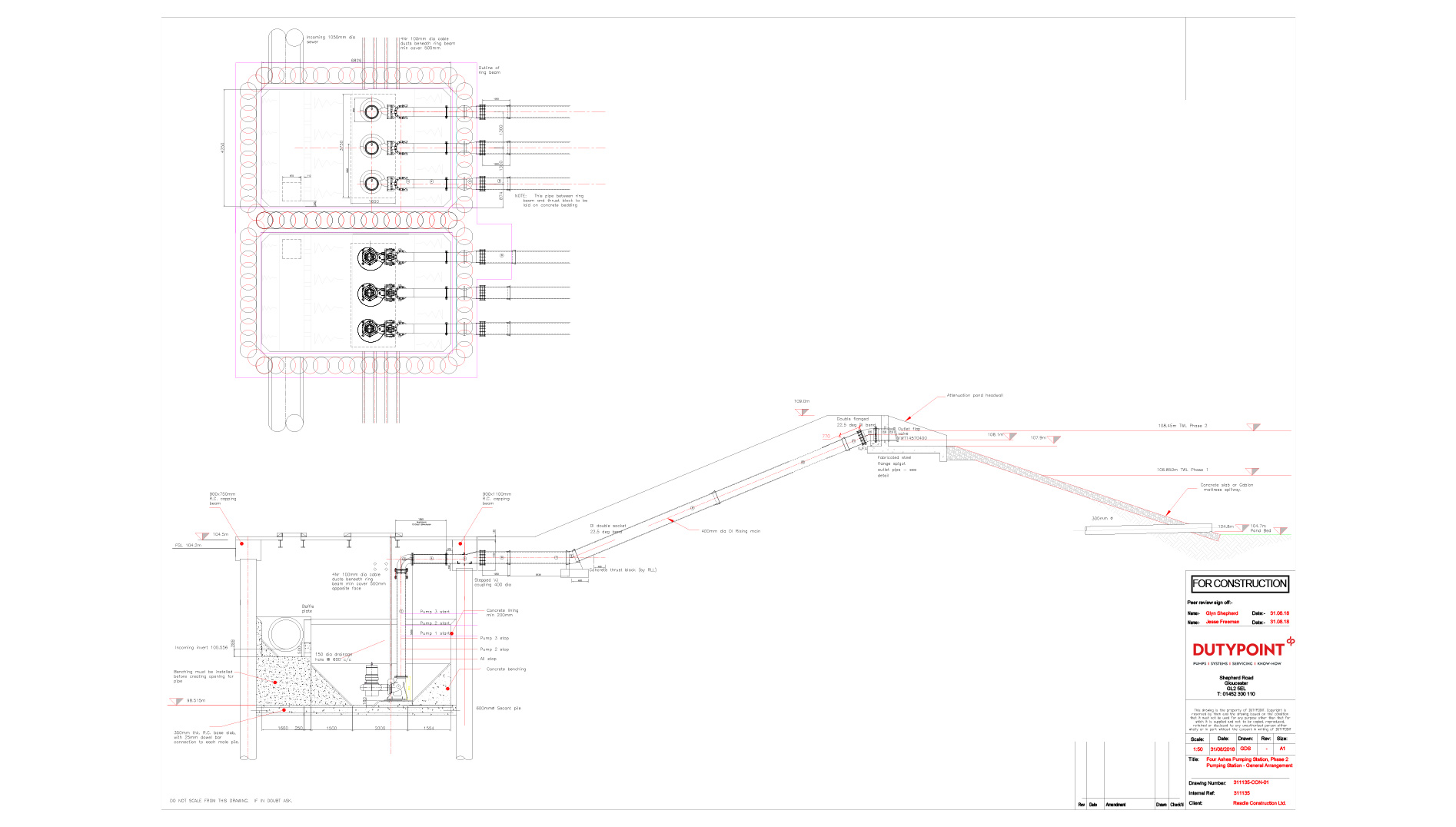

Dutypoint worked closely with the consultant to provide a hydraulically designed solution for the client. This included the design of the wet-well chamber, the rising main and the headwall to handle around 1000l/per second of water which is fed by a large network of underground drainage pipes across the site.

Dutypoint carried out the full mechanical and electrical install working closely with the contractor who carried out all of the concrete construction. Furthermore, by using Dutypoint’s new state-of-the-art PLC control interface, the pump station could be monitored remotely, enabling our service team to closely monitor and adjust the performance of the pump station as needed.

Lloyd Preston

Lloyd Preston  6 June 2019

6 June 2019