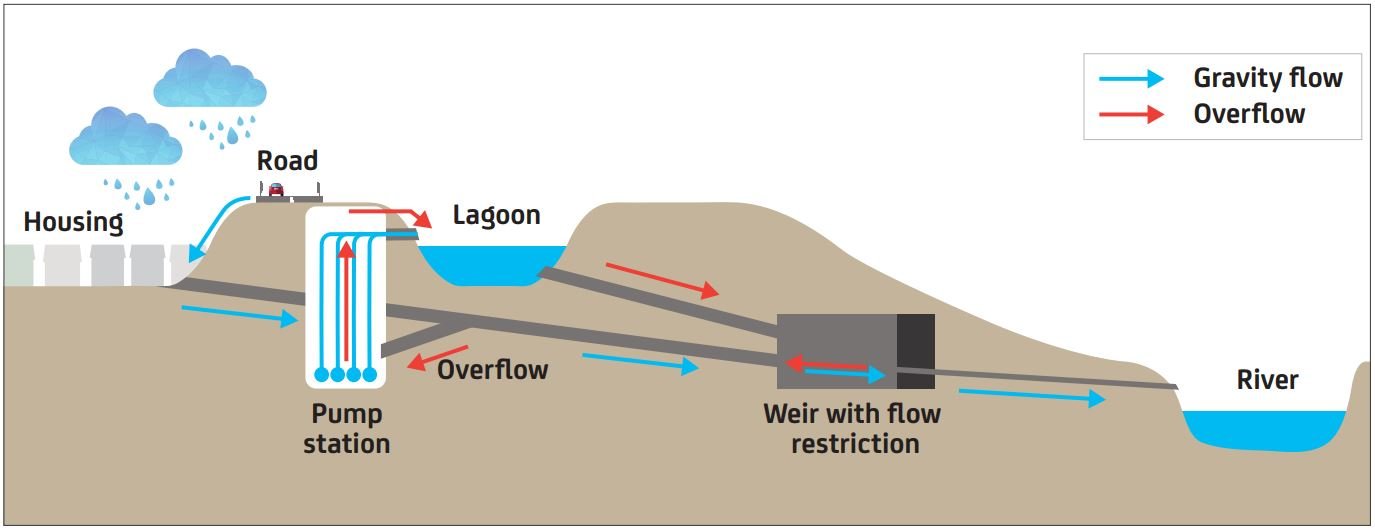

Where gravity drainage cannot be relied upon to move sewage or wastewater from a building to a nearby sewer or sewage treatment plant, a pumping station may be required.

A pumping station is a mechanical device installed in a basement, cellar, sewer, water system or other liquid-carrying pipeline to move wastewater to a higher level and usually consists of one or more submersible pumps installed in a chamber. They are also known as sump pumps, sewage stations or pump chambers.

The traditional solution has been to build a pumping station on site, which consists of a chamber made from concrete rings, which is then fitted out with the necessary equipment, i.e., pumps, pipes, and valves. However, this method can be time consuming as it can take a number of weeks to complete the construction. This method can also create challenges in terms of onsite access, logistics and confined working constraints.

A more efficient and cost effective solution is the modern packaged pumping station, which as the name suggests, come as a complete package containing all the essential elements ready for installation. Packaged pumping stations are typically prefabricated, manufactured offsite and delivered to site ready for installation, which saves significant program time and thus project cost. By being designed, built and tested to the appropriate standards offsite, packaged pumping stations can be installed much more quickly onsite.

Common applications can include domestic dwellings located downhill from the sewer or treatment plant, new homes built on more remote or inaccessible land, larger commercial buildings such as schools, hospitals and care homes and industrial buildings such as factories, warehouses and major infrastructure projects such as new roads, all facing the same challenge of how to effectively pump wastewater to a treatment plant.

Typically featuring a tank constructed from super strong materials including glass-reinforced plastic (GRP) or polyethylene, packaged pumping stations can be specified with a macerator type submersible pump(s) to effectively break up larger particles within the liquid, these are typically used when pumping sewage or slurry. They can also be fitted with control or monitoring equipment to provide an early alert of any problems with the system.

Packaged pumping stations are available in a variety of sizes and designs to suit the specific requirements of the application. They are designed so that they do not emit any odour and because they are located underground they are generally very quiet.

Dutypoint offers a range of great value, easy to install Vortech™ Packaged Pumping Stations made from both GRP and polyethylene and offers an online product selector to enable the easy configuration of an underground sewage or wastewater pumping station to suit the specific needs of the project.

Vortech™ Packaged Pumping Stations are available in a choice of sizes with different pump options to suit the specific application including pumps for surface water, pumps for foul water/sewage and heavy duty grinder pumps for sewage with all models delivered as a complete package, ready for installation, and for added convenience selected models are available in stock with FREE same or next day delivery.

Key features of the Vortech™ range include super strong chambers made of virgin polyethylene, featuring strengthening ribs for superior quality and corrosion resistance, and a compact design constructed to fit in tight areas such as basements and cellars.

Vortech™ Packaged Pumping Stations are also available in a choice of chamber sizes, ranging from 280 litres all the way up to 9,000 litres with high level alarms fitted as standard with the option to include battery backup control systems for critical applications.

Dutypoint also offers a range of GRP packaged pumping stations that can be designed to suit the specific requirements of your project and our brand new QuikForm™ underground packaged pumping station with utilises an innovative shuttering system to reduce installation labour hours by 35% and concrete usage by up to 50%*

Lloyd Preston

Lloyd Preston  16 January 2020

16 January 2020