Adoptable Pumping Station

Adoption of a pump station can be an intimidating task. The Dutypoint team are always on hand to assist. The adoptable pumping station will need to be designed and installed in line with the local water companies’ addendum of Section 104 of the Water Industry Act 1991 specification. This compliance allows the local water company to take responsibility for future maintenance and running costs.

Dutypoint also offers a full design, installation, commission, and support adoption with the local water company.

Product specification

Product overview

– Design and liaison with the local water authority

– Mechanical, electrical and commissioning of a pump station on site

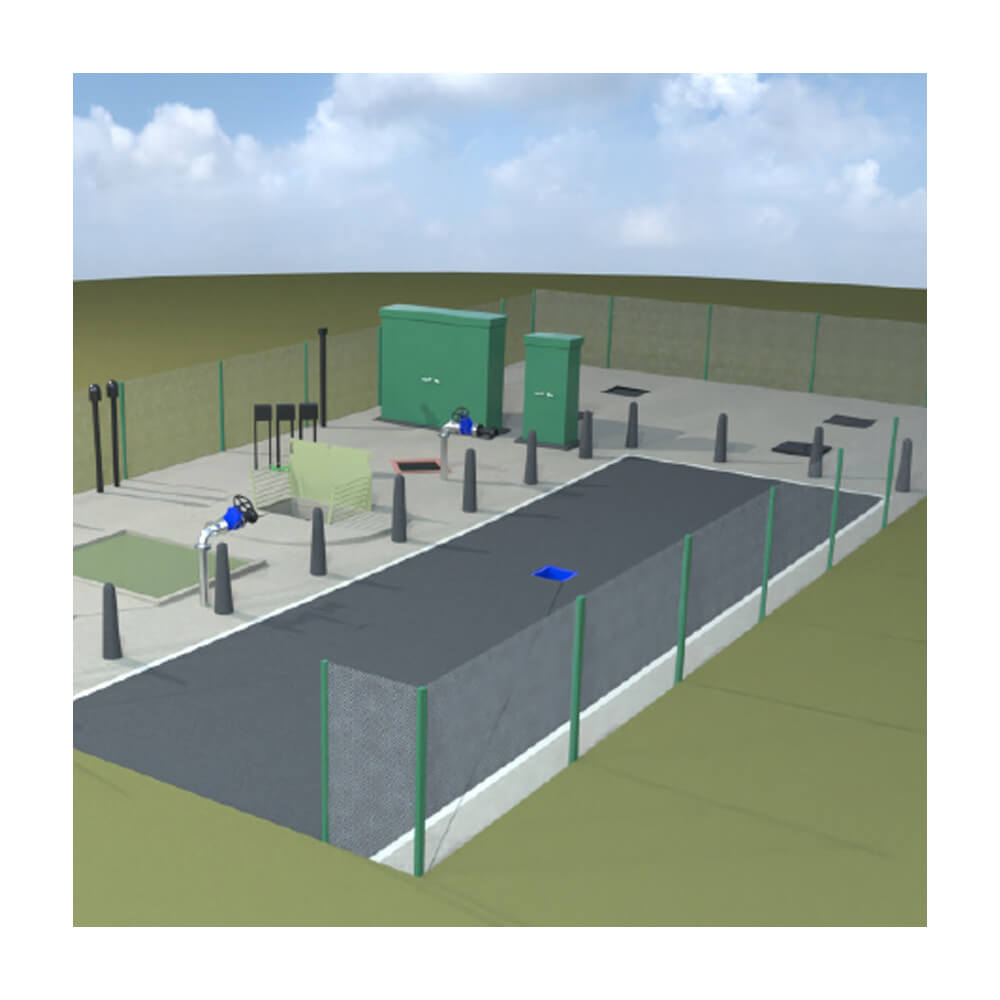

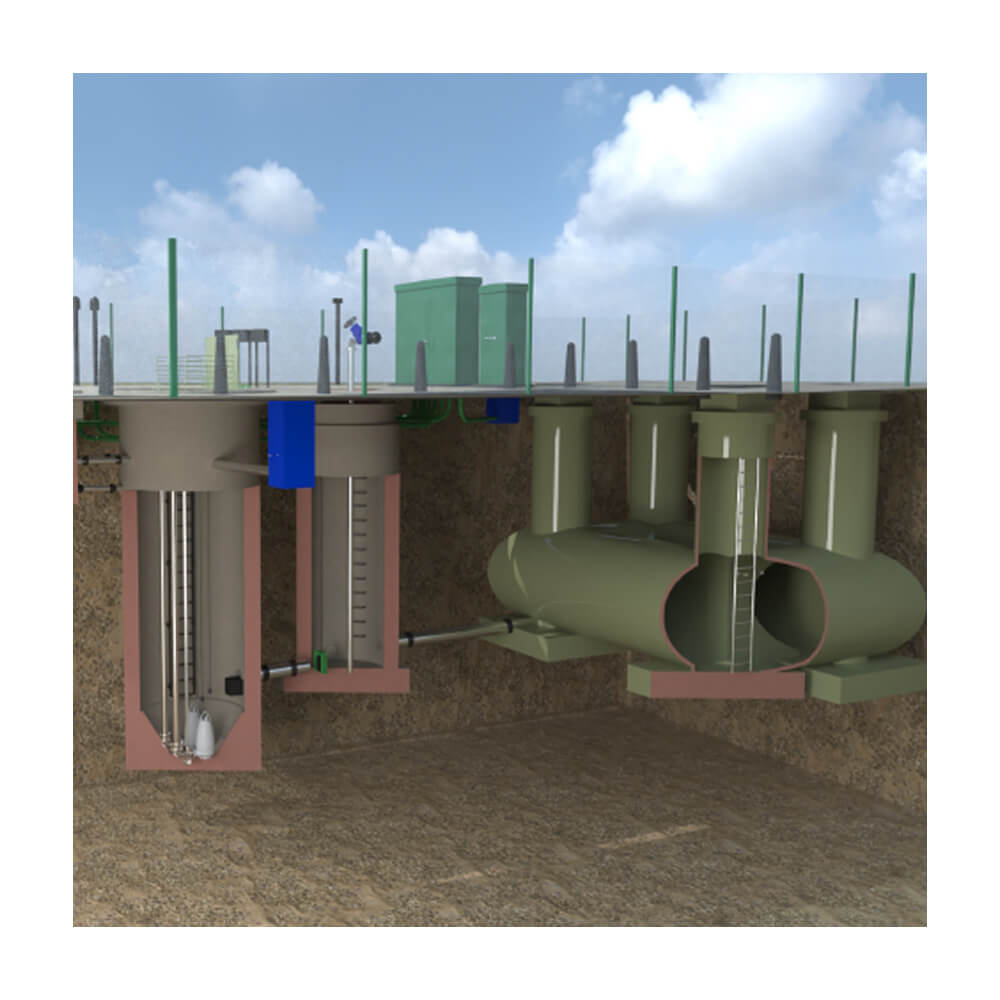

– Inlet chambers, wet well and valve chambers

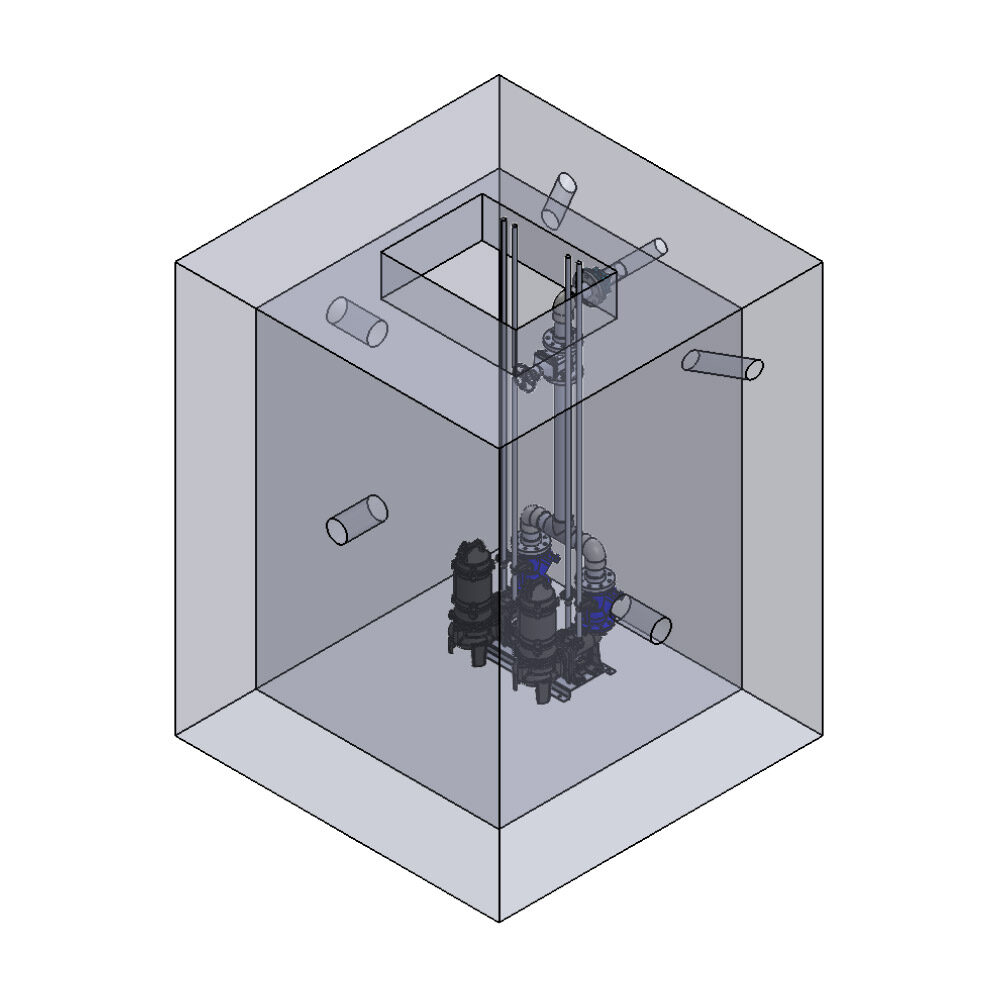

– ATEX-rated pumps

– Compliant control panel with GRP kiosk

– High-grade pipework and valves

– Various level control types

– Heavy-duty access covers

Additional options

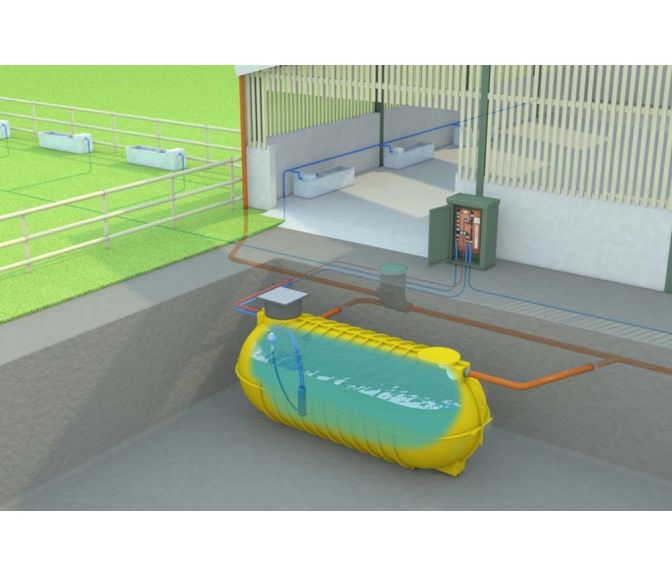

– Dosing systems

– Flow meter chambers

– Combined panel for storm and foul applications

– Attenuation tanks

– Baffle plates

– Penstock valves

1. Preliminary budget quote

A high-level design and budget proposal is issued. The proposal includes a separate price for undertaking the S104 design.

2. Letter of intent/PO for design received

Dutypoint proceed with a detailed design for S104 application. In order for the design to commence, key site information is required, such as:

– Site plan showing proposed location of PS

– Sewer network drainage design for catchment area

– Inflow details (DWF/Average/Peak)

– Details/timings of phased occupancy, if applicable

– Rising main route plan and long section

3. Detailed design

A high-level design and budget proposal is issued. The proposal includes a separate price for undertaking the S104 design.

4. First iteration of design submitted

At this point, we are able to provide a definitive quote (subject to design approval).

5. Design review/revisions

During this period, there is usually feedback from the Water Board. Dutypoint will liaise directly with the Water Board to address queries and action change requests until the design is signed off. This may be a short process or take several months, depending on the Water Board response times and scheme complexity.

6. Design approval

Once written approval has been received from the Water Board, a final confirmed quotation can be issued for the supply and installation of the pumping station.

7. Full order received

Orders are placed for all the equipment and site work planning commences. The supply and installation lead time starts from this point.

8. Pre-start meeting

A pre-start meeting is arranged between Dutypoint and the contractor to confirm timescales, scope and responsibilities.

9. Install visit 1

Stage 1 of installation involves fitting pipework and valves within a wet well and valve chambers. Typical pre-visit site requirements include:

– Wet well constructed up to the underside of the cover slab level

– Valve chamber base complete with concrete pipe supports

– Ground left exposed between chambers at pipework level

10. Install visit 2/commissioning

Stage 2 involves installing the pumps, controls and instrumentation and commissioning of the system. Typical pre-visit site requirements include:

– Compound civil works completed, including all cover slabs, cable ducts, kiosk plinths etc.

– Control kiosk installed

– Permanent power supply connected to control panel mains incomer

– Rising main installed and connected, tested and live

11. Pre-adoption maintenance period

The Water Board will typically require a certain minimum level of occupancy before they will adopt the pumping station. Up until this point, it is the contractor’s responsibility to monitor and maintain the system.

Dutypoint can offer a maintenance service during this period, including simple, cost-effective GSM telemetry monitoring.

12. Site handover

When the Water Board are ready to adopt, they will arrange a site inspection. Dutypoint can attend the site during the inspection/handover process to answer queries, if required.