VT2-05-005M

0.55

230/1/50

6.6

VT2-05-005T

0.55

400/3/50

3.8

VT2-05-007M

0.75

230/1/50

6.6

VT2-05-007T

0.75

400/3/50

3.8

VT2-05-011M

1.1

230/1/50

9.4

VT2-05-011T

1.1

400/3/50

5.4

VT2-05-015M

1.5

230/1/50

11.8

VT2-05-015T

1.5

400/3/50

6.8

VT2-05-022M

2.2

230/1/50

16

VT2-05-022T

2.2

400/3/50

9.2

VT2-05-030M

3

230/1/50

20.8

VT2-05-030T

3

400/3/50

12

VT2-10-011M

1.1

230/1/50

9.4

VT2-10-011T

1.1

400/3/50

5.4

VT2-10-022M

2.2

230/1/50

16

VT2-10-022T

2.2

400/3/50

9.2

VT2-10-030M

3

230/1/50

20.8

VT2-10-030T

3

400/3/50

12

VT2-10-040M

4

230/1/50

26.4

VT2-10-040T

4

400/3/50

15.2

VT2-10-055T

5.5

400/3/50

21

VT2-15-015M

1.5

230/1/50

11.8

VT2-15-015T

1.5

400/3/50

6.8

VT2-15-030M

3

230/1/50

20.8

VT2-15-030T

3

400/3/50

12

VT2-15-040M

4

230/1/50

26.4

VT2-15-040T

4

400/3/50

15.2

VT2-15-055T

5.5

400/3/50

21

VT2-20-022M

2.2

230/1/50

16

VT2-20-022T

2.2

400/3/50

9.2

VT2-20-040M

4

230/1/50

26.4

VT2-20-040T

4

400/3/50

15.2

VT2-20-055T

5.5

400/3/50

21

VT3-05-005M

0.55

230/1/50

9.9

VT3-05-005T

0.55

400/3/50

5.7

VT3-05-007M

0.75

230/1/50

9.9

VT3-05-007T

0.75

400/3/50

5.7

VT3-05-011M

1.1

230/1/50

14.1

VT3-05-011T

1.1

400/3/50

8.1

VT3-05-015M

1.5

230/1/50

17.7

VT3-05-015T

1.5

400/3/50

10.2

VT3-05-022M

2.2

230/1/50

24

VT3-05-022T

2.2

400/3/50

13.8

VT3-05-030M

3

230/1/50

31.2

VT3-05-030T

3

400/3/50

18

VT3-10-011M

1.1

230/1/50

14.1

VT3-10-011T

1.1

400/3/50

8.1

VT3-10-022M

2.2

230/1/50

24

VT3-10-022T

2.2

400/3/50

13.8

VT3-10-030M

3

230/1/50

31.2

VT3-10-030T

3

400/3/50

18

VT3-10-040M

4

230/1/50

39.6

VT3-10-040T

4

400/3/50

22.8

VT3-10-055T

5.5

400/3/50

31.5

VT3-10-075T

7.5

400/3/50

43.5

VT3-15-015M

1.5

230/1/50

17.7

VT3-15-015T

1.5

400/3/50

10.2

VT3-15-030M

3

230/1/50

31.2

VT3-15-030T

3

400/3/50

18

VT3-15-040M

4

230/1/50

39.6

VT3-15-040T

4

400/3/50

22.8

VT3-15-055T

5.5

400/3/50

31.5

VT3-15-075T

7.5

400/3/50

43.5

VT3-20-022M

2.2

230/1/50

24

VT3-20-022T

2.2

400/3/50

13.8

VT3-20-040M

4

230/1/50

39.6

VT3-20-040T

4

400/3/50

22.8

VT3-20-055T

5.5

400/3/50

31.5

VT3-20-075T

7.5

400/3/50

43.5

Manuals

|

Installation, operation and maintenance manual for the VT range of booster sets. |

|

Brochure

|

A technical overview of the Dutypoint VT. |

|

Certificate

|

VT Booster - Kiwa Regulation 4 (KUKreg4) Certification. |

|

|

VT Booster - WRAS Approval Certification. |

|

Manuals

|

Installation, operation and maintenance manual for the VT Booster range. |

|

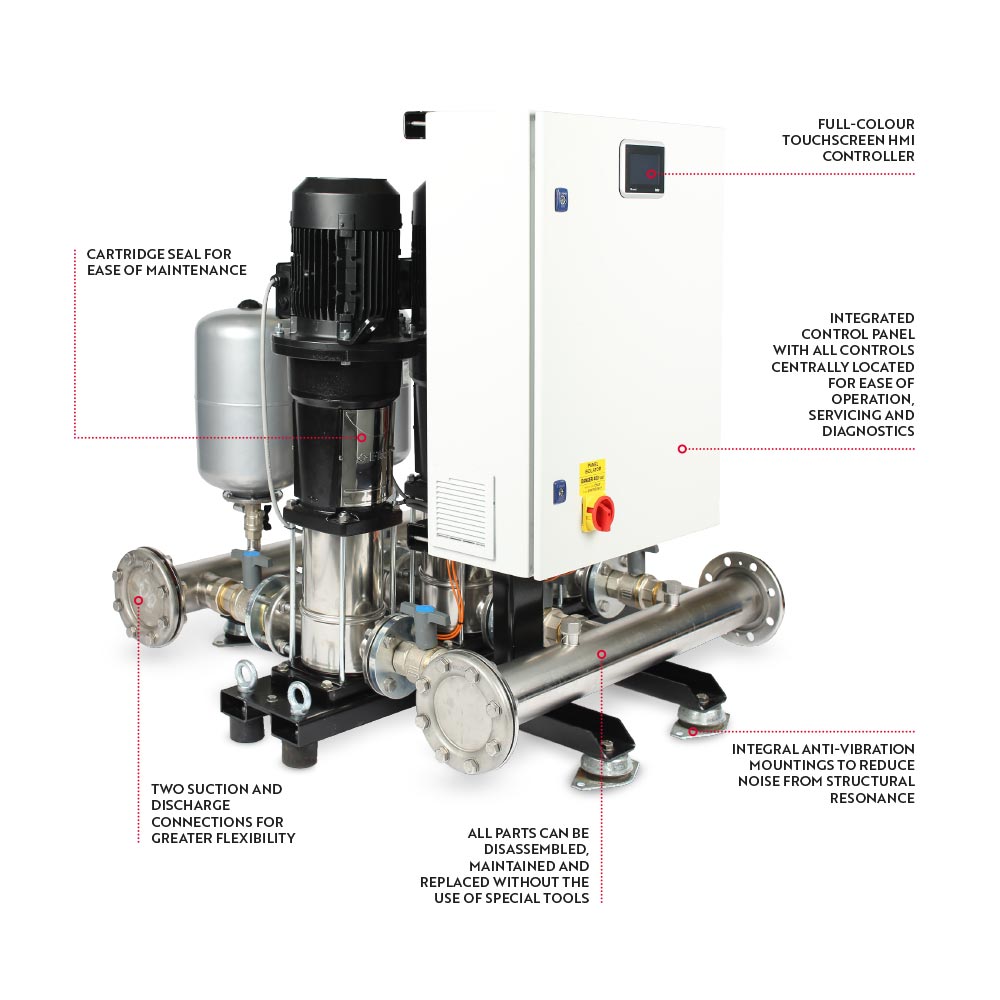

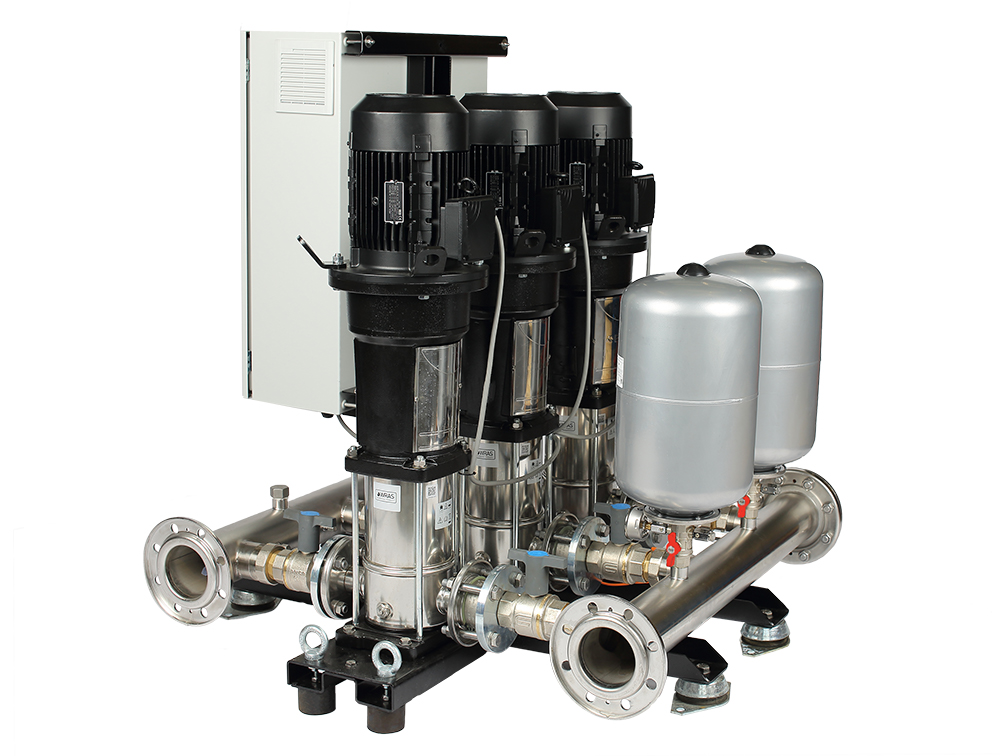

Product overview

– Multistage vertical pumps

– Low-water protection technology that deactivates the pumps if there is no water in the break tank, protecting against dry running

– Anti-vibration mounts reduce system noise

– Anti-seize technology during low or zero usage

– Burst pipe protection that constantly monitors the system for signs of major leakage

– Full-colour touchscreen display with clear error display and log

– IP55-rated control panel allows for simple and safe maintenance

– Cyclic duty changeover ensures even wear across pumps

– Common fault volt-free contact for connection to building management systems

– External start/stop contact for connection to external control systems

– RS485 connections for connection to Modbus

Pressure range

2.5 – 10 bar

Max system pressure

15 bar

Controller type

Inverter integral to panel

Max system temperature

40°C

Noise data

Motor at 3600 rpm < 70LpA (dB +/-2)*

*More specific details available on request.

Manifolds

AISI 304 stainless steel

Isolation valves

Nickel-plated brass

Non-return valves

AISI 304 stainless steel

Pressure transducers

AISI 304 stainless steel

Pump casing

AISI 304 stainless steel

Pump impellers

AISI 304 stainless steel

Mechanical seals

Silicon carbide, graphite, EPDM

Pressure vessels

WRAS approved

Base plate

Powder-coated mild steel