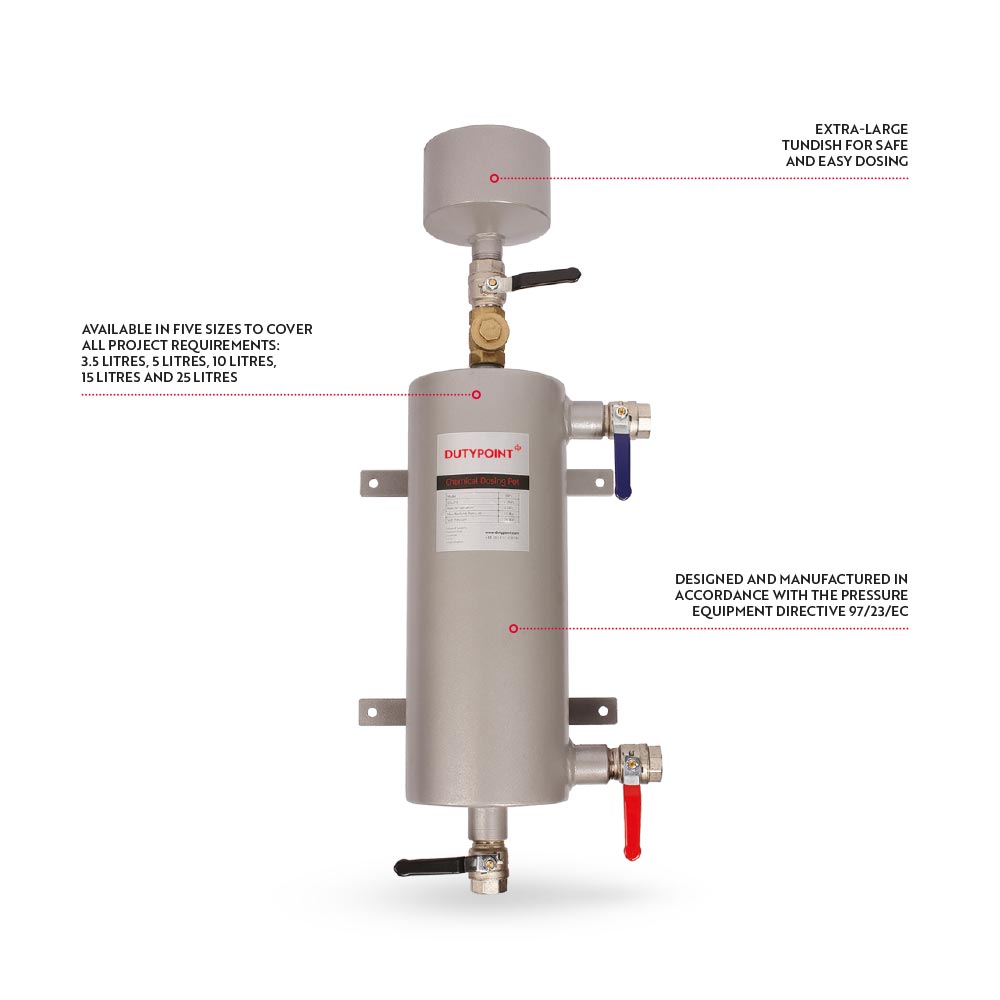

Chemical Dosing Pots

Dutypoint dosing pots are supplied as a complete package with all valves and tundish fitted to minimise on-site installation times. These cost-effective, easy-to-install units facilitate simple, regular ongoing maintenance of your heating or chilled water system.

Dutypoint dosing pots feature a top-mounted, manual air vent that can be opened during the filling operation to minimise air ingress into the system.

For your safety, each Dutypoint dosing pot is fitted with an integral safety valve that prevents fluid from escaping under pressure if the top entry valve is opened before the flow and return valves are closed. Also, each unit is individually hydrostatically tested to 16 bar prior to despatch for your peace of mind.

The standard Dutypoint range includes five different unit sizes to cover all your requirements: 3.5 litres, 5 litres, 10 litres, 15 litres and 25 litres.

Product specification

Manuals

| Sizing, installation and operation instructions for Dutypoint Chemical Dosing Pot range. |

Brochure

| A technical overview of Dutypoint chemical dosing pots. |

SIZING

The size of the dosing pot installed in a system is not critical as multiple doses of chemicals can be put into the system to reach the correct concentration. A smaller unit is easier to handle physically and allows for more accurate dosing. However, the time on site for performing multiple doses has to be considered; this factor should influence your decision when selecting dosing pots.

Note: Chilled water systems often require large volumes of glycol to be dosed into the system; a larger dosing pot may be required for chilled water systems.

The formula below can be used as a guide to help you in your selection:

Boiler power (kW) x 12 litres/kW x 0.01 (based on 1% concentration*) = volume of chemical required

Example: Boiler power 250 kW x 12 litres x 0.01 = 30 litres of chemical.

You could use any of the following dosing pots for this installation:

– 5 litre – dose six times

– 10 litre – dose three times

– 15 litre – dose two times

*Confirm the required concentration level for the chemical being used.

SPECIFICATION

OPERATING PARAMETERS

APPROVALS

Designed and manufactured in accordance with the Pressure Equipment Directive 97/23/EC.