CXA – Air Separators

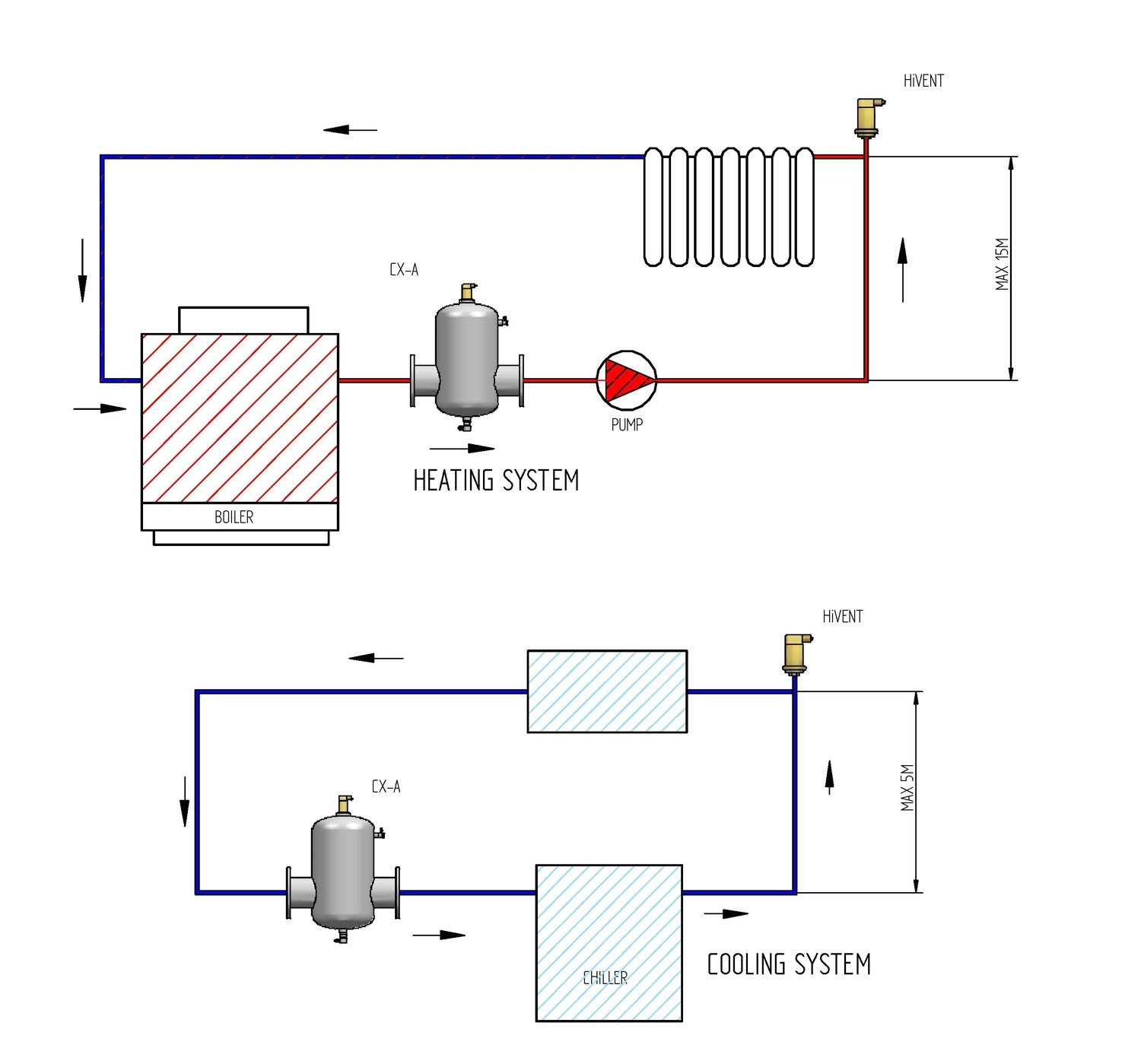

Dutypoint CXA air separator units are installed to efficiently remove air and microbubbles from the system.

In heating systems, an air separator should be installed in the flow loop where the system experiences the highest temperature (next to the heat source) and lowest pressure. Air separators should ideally be installed immediately after the boiler and prior to the pump suction port as this is where the formation of microbubbles is greatest. In a chilled water system, the unit must be located in the return loop just prior to the chiller.

Product specification

STANDARD TECHNICAL FEATURES

– Efficient removal of air and microbubbles in pipework

– Stainless steel element

– Designed and manufactured in accordance with the Pressure Equipment Directive 97/23/EC

OPTIONS

– Larger units up to DN600 available on request

– Non-standard connections